Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

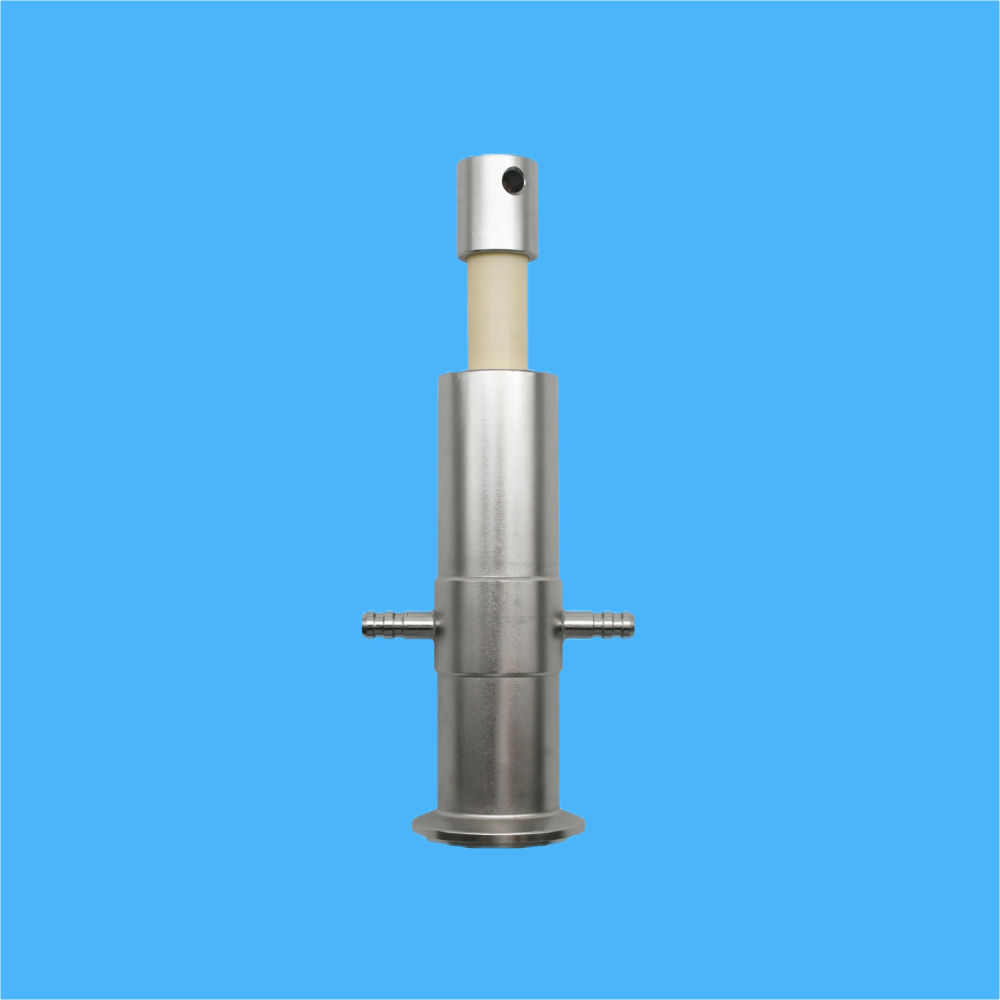

Ceramic metering pump

HOMECeramic metering pump

High-precision ceramic micro-suction pump

High-precision ceramic micro-suction pump

To understand the high-precision micro-liter ceramic pump, I'll first present the conclusion, and then explain it key points and tables.

The conclusion first: A high-precision micro-liter ceramic pump is a precision pump device that uses ceramic material as its core components and focuses on delivery of micro-liter (μL) level liquid. Its core advantages are corrosion resistance, wear resistance, and high precision, and it is widely used in lithium battery, pharmaceutical food, and other fields.

Core definition and characteristics

The high-precision micro-liter ceramic pump is a kind of pump device designed for the delivery of micro-ities of liquid (usually 10–1000 microliters, some models can reach 4–80 microliters)15, which high-performance ceramics (such as alumina, zirconia) as key components (such as impellers, plungers). Its core characteristics include:

High precision: The filling precision is generally within ±0.3%–±0.5% (within three to five thousandths)3.

Withstand extreme environments The ceramic material endows it with corrosion resistance, wear resistance, and high-temperature resistance.

Wide range of scenarios: It can handle materials with particles (such as seeds), high viscosity (sauces), and corrosive materials.

🧩 Key parameters and application scenarios

Parameter Category Typical Range Application Domain Example Flow range 4–80 μL to 0.5–20 mL Lithium battery fluid injection, pharmaceutical reagent filling, cosmetic essential oil

Precision ±0.3%–±0.5% High-precision metering (such as centrifuge tube filler, sauce bag filler)3

Drive mode Stepper motor, servo motor, pneumatic Automated production line (electric), high-speed filling (pneumatic)

in contact with materials Ceramics, SUS316L, PTFE Corrosive liquids (such as chemical raw materials), food-grade

Core advantages and technical key points

Its advantages come from the ceramic material and structural design:

Ceramic components: Impellers/plungers are of alumina, zirconia, and other ceramics, with wear resistance far exceeding that of metal, extending the service life24.

Precise control: servo motor or pneumatic drive, it can achieve stable delivery of micro-flows, adapting to the needs of micro-filling.

Multi-functional adaptation Support for non-standard customization (such as multi-column pumps, with back suction function), can handle pastes, granular materials, and solve process problems such as3.

Should I organize a comparison table of mainstream models for you to quickly screen applicable scenarios and parameters?