Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Medical ceramic pump

HOMEMedical ceramic pump

0 - 5ML Pharmaceutical Filling Pump

Pharmaceutical ceramic pumps, pharmaceutical filling metering pumps and pharmaceutical ceramic filling pumps are commonly used in the pharmaceutical industry for precise liquid filling and measurement. They utilize the high precision and corrosion resistance of ceramic materials to ensure the purity and filling accuracy of medicines. When choosing, it is necessary to consider actual needs to ensure the stability and safety of the product.

Pharmaceutical ceramic pump filling - Pharmaceutical filling metering pump - Pharmaceutical ceramic filling pump has the following features:

Using high-performance technical ceramic materials, it features high hardness, good wear resistance, high temperature resistance, and corrosion resistance. The material performance is guaranteed to be reliable.

The micro-porous structure on the working surface of the plunger, obtained through a unique processing method, has self-lubricating properties, which has changed the traditional mechanism of sliding friction and lubrication in piston pumps.

The inner surface is designed with a fluid structure, featuring no dead corners or grooves. The inner surface is precisely machined to a mirror finish by advanced high-precision internal and external cylindrical grinding machines, and the outer surface is vibrated polished for easy cleaning and disinfection.

The pump body structure is made of 316L stainless steel with sealing, which is easy to disassemble.

The shape and size can be designed and processed according to the user's requirements.

1. Pharmaceutical Ceramic Pump Filling - Pharmaceutical Filling Metering Pump - Technical Specifications of Pharmaceutical Ceramic Filling Pump

The ceramic piston metering pump features high-precision measurement accuracy, simple operation, ease of disassembly and installation, disinfection and cleaning capabilities. It is available in various specifications ranging from 1ml to 100ml. By taking advantage of the ceramic's resistance to acid, alkali, high temperature and wear, the production of the ceramic pump can maintain stable filling volume over time. It is not prone to clogging when cold or hot, and its service life is significantly improved compared to stainless steel pumps. It complies with GMP standards.

| type: | piston diameter(MM) | Volume(ML) |

| JC-06 | D6.35 | 0-0.7 |

| JC-10 | D10 | 0-5 |

| JC-15 | D15 | 0-10 |

| JC-20 | D20 | 0-20 |

Pharmaceutical ceramic pump filling - Pharmaceutical filling metering pump - Structure of pharmaceutical ceramic filling pump:

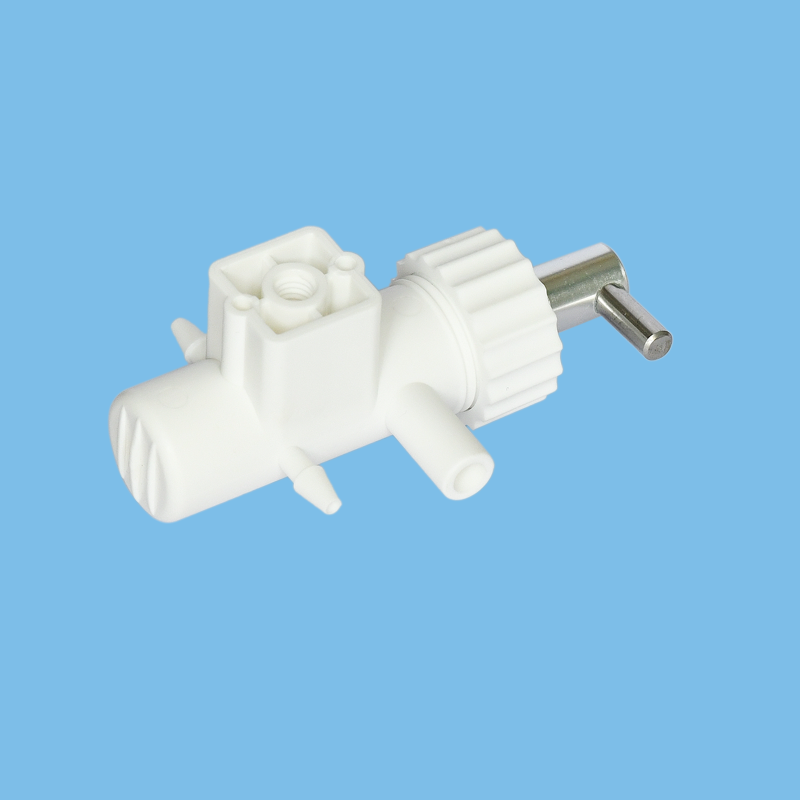

The ceramic filling metering pump is composed of a ceramic pump body, a rotating valve, a metering rod, a stainless steel inlet and outlet nozzle, and connecting parts, etc.

Pharmaceutical ceramic pump filling - Pharmaceutical filling metering pump - Structure of pharmaceutical ceramic filling pump: Working principle of ceramic filling metering pump:

The opening of the rotary valve aligns with the liquid inlet, and the downward linear movement of the ceramic column creates negative pressure and sucks in the liquid.

The opening of the rotary valve aligns with the liquid inlet, and the downward linear movement of the ceramic column creates negative pressure and sucks in the liquid.

III. Assembly of Pharmaceutical Ceramic Pumps for Filling - Pharmaceutical Filling Metering Pumps - Assembly of Pharmaceutical Ceramic Filling Pumps and Connection with Filling Machines

Since the ceramic rods and ceramic sleeves are precision-matched components with very small gaps and cannot be interchanged; the products have been numbered before leaving the factory, and they must not be interchanged during cleaning and assembly.

Before installation, ensure that all sealing components are properly installed and there is no leakage.

It is necessary to eliminate the assembly clearance between the various components of the filling machine (the assembly clearance causes changes in stroke, thereby leading to inaccurate measurement), and it is also necessary to ensure the coaxiality of the moving parts (this affects the service life of the pump and the accuracy of the filling volume).