Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

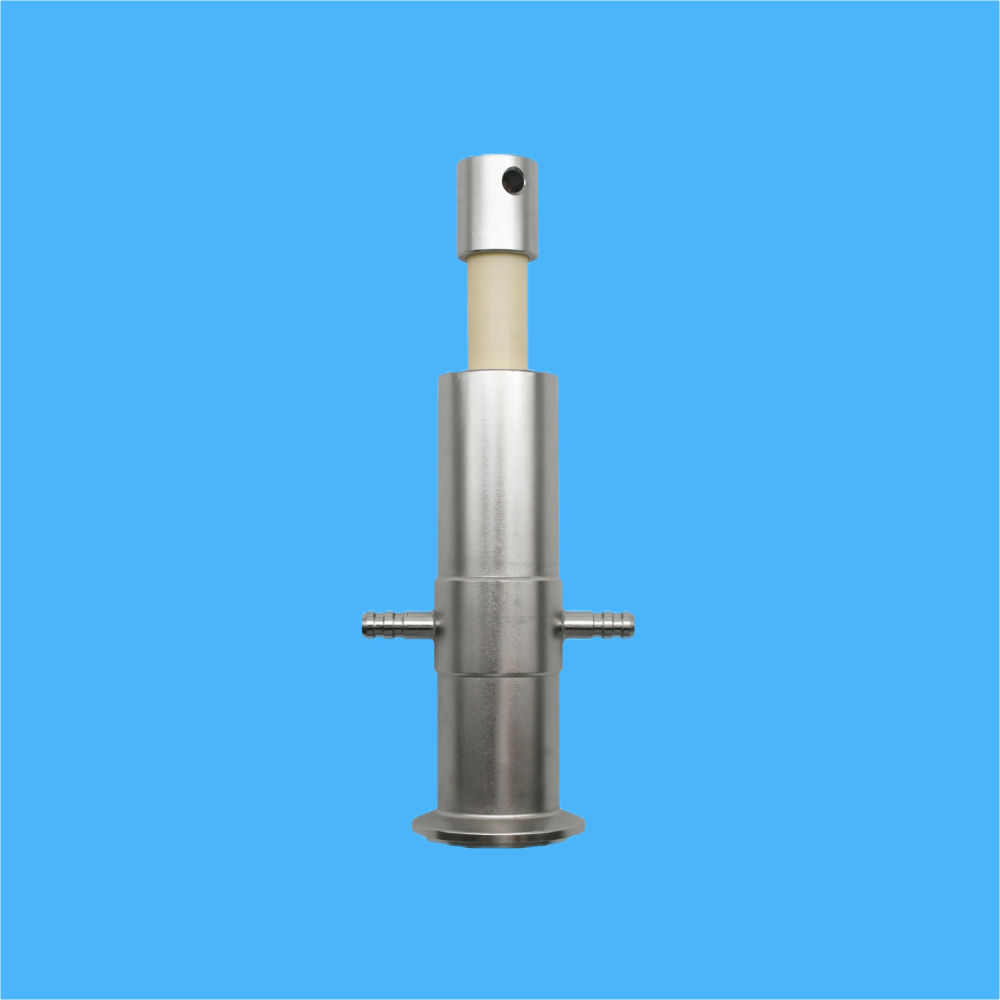

Chemical ceramic pump

HOMEChemical ceramic pump

Wear-resistant ceramic pump

Wear-resistant ceramic pump,Ceramic pumps, ceramic piston pumps and zirconia ceramic pumps possess excellent corrosion resistance, wear resistance and high precision. They are suitable for industries such as chemical and pharmaceutical. These pumps can ensure the purity and transmission accuracy of fluids, thereby enhancing production efficiency.

Ceramic pumps - Ceramic piston pumps - Zirconia ceramic pumps have the following product models:

| type: | piston diameter(MM) | volume(ML) |

| JC-20 | D20 | 5 |

| JC-22 | D22 | 8 |

| JC-25 | D25 | 10 |

| JC-30 | D30 | 15 |

| JC-36 | D36 | 20 |

Ceramic pump - Ceramic piston pump - Structure of zirconia ceramic pump:

The ceramic filling metering pump is composed of a ceramic pump body, a rotating valve, a metering rod, a stainless steel inlet and outlet nozzle, and connecting parts, etc.

Working principle of the ceramic filling metering pump:

The opening of the rotary valve aligns with the liquid inlet, and the downward linear movement of the ceramic column creates negative pressure and sucks in the liquid.

The opening of the rotary valve aligns with the outlet, and the ceramic column undergoes linear movement towards the upper end, creating positive pressure and discharging the liquid.

Ceramic filling pump - Ceramic pump filling - Assembly of filling pump and connection with filling machine:

Ceramic filling pump - Ceramic pump filling - Assembly of the filling pump and connection with the filling machine. Since the ceramic rod and the ceramic sleeve are precision-matched components with very small gaps and cannot be interchanged; the product has been numbered before leaving the factory, and they must not be interchanged during cleaning and assembly.

Before installation, ensure that all sealing components are properly installed and there is no leakage.

It is necessary to eliminate the assembly clearance between the various components of the filling machine (the assembly clearance causes changes in stroke, thereby leading to inaccurate measurement); it is also necessary to ensure the coaxiality of the moving parts (this affects the service life of the pump and the accuracy of the filling volume).

Ceramic pump - Ceramic piston pump - Advantages of zirconia ceramic pump:

It can increase the lifespan by 5 to 10 times compared to metal cylinder liners.

It has the advantages of being wear-resistant, corrosion-resistant, resistant to high pressure, resistant to high temperature, having high strength and high hardness.

Reduce the transportation costs, maintenance costs, labor costs, storage costs, etc. in the drilling operation.

Reduce the transportation costs, maintenance costs, labor costs, storage costs, etc. in drilling operations;

Ceramic pump - Ceramic piston pump - Zirconia ceramic pump typical applications:

Biological industry: Diagnostic reagents, nucleic acids, vaccines, anticoagulants for blood collection tubes, gels, oral products, DMA analyzers, packaging, filling of test tubes, addition and spraying of blood sample collection reagents, and production of liquid medicine, etc.

Energy industry: Quantitative filling and sealing equipment for button batteries, cylindrical batteries, capacitors, polymer batteries, power batteries, lead-acid batteries, zinc-air batteries, as well as battery glove boxes, and automatic/hybrid filling machines and other equipment manufacturers.

Electronic industry: AF coating, silver paste, VC, heat pipes, optical lenses, microelectronics, etching and cleaning solutions during semiconductor manufacturing, LED chip dispensing and packaging, LCD precise spraying, micro dispensing machines and other supporting equipment.

Chemical industry: COD water pollution detection reagents, sulfuric acid filling, hydrochloric acid, nitric acid, fluoroboric acid, disinfectants, ink, paper strength enhancers, dye quantitative addition, control agent addition, slaked lime addition, etc.

Cosmetics industry: Emulsions, essential oils, mascara, facial cleansers, cosmetics, skin care creams, hair dyes, fatty acids, additives for cosmetic pigments, humidity control, and addition of fragrances for filling.

Food Industry: Tomato puree, milk, yogurt, cream, soda, juice, wine, seasonings, mustard, condiments, honey, butter, fruit juice puree, pudding, yogurt food additives, flavorings, edible oil packaging, etc.