Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Food filling pump

HOMEFood filling pump

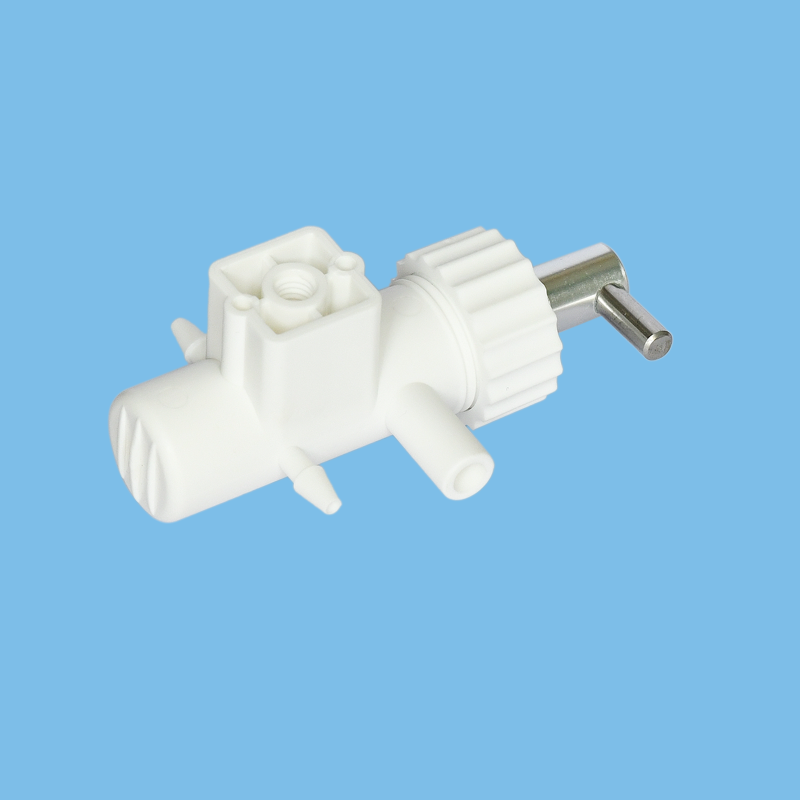

Medical 10ml Filling Pump

Pharmaceutical filling pumps are core equipment used in the precise and aseptic filling of pharmaceutical liquids in the fields of pharmaceuticals, biotechnology, etc. core value lies in ensuring asepsis, metering accuracy, and process stability, which directly affects the quality of the drug product and the compliance of production

Main Types and Characteristics

Ceramic Pump Filler: Adopting the principle of squeezing soft tubes, only the soft tube into contact with the drug solution, eliminating the risk of leakage, easy to clean, and especially suitable for scenarios with high hygiene requirements. The filling accuracy can reach ±2%, for laboratory to pilot-scale production.

Magnetically Driven Pump Filler: Achieving no leakage through magnetic force driving, the filling error can be controlled ±0.5%, suitable for filling quantities from 200ml to 20L, and supports high viscosity liquids.

Ceramic Pump: Using materials such as zirconia, it is corrosion-resistant and wear-resistant, suitable for high-precision metering and corrosive drug solutions, such as blood cell counters micro pumps.

Metering Pump: Measuring volume through the reciprocating motion of the piston, with high precision and a wide range of adjustments (such as12CC specifications), suitable for oil systems, fuel systems, etc.

Selection Suggestions

High Hygiene Requirements: Priority should be given to the use of pumps or ceramic pumps.

Large Volume Filling: Consider using magnetic drive pumps or metering pumps.

High Precision Requirements: Choose a ceramic metering pump