News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

The structure and principle of ceramic pumps

2025-12-15 08:26:51 View:149The structure and principle of ceramic pumps

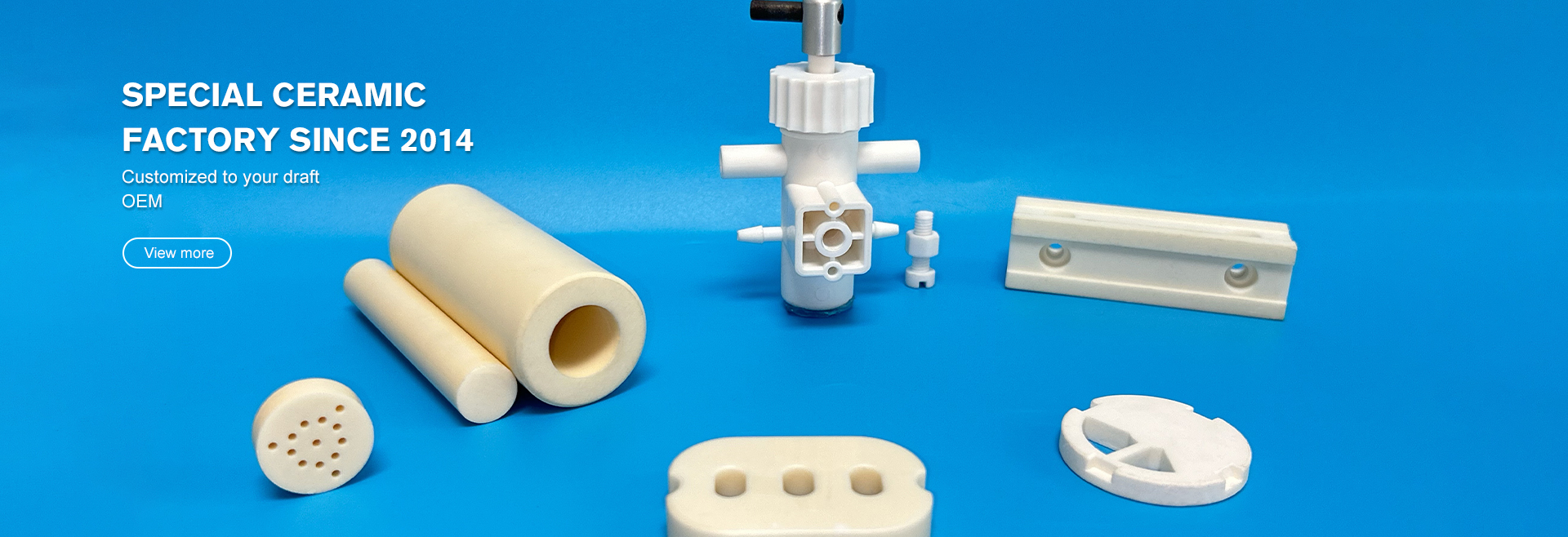

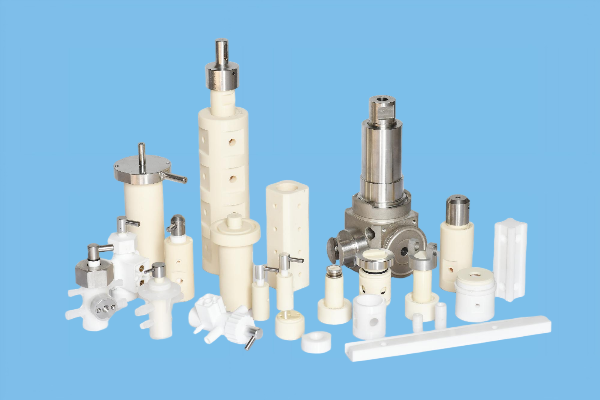

The core structure of ceramic pumps uses ceramic materials (such as alumina, siliconide) to manufacture critical flow parts. Its working principle is divided into two categories: centrifugal and volumetric. Fluid transportation is achieved throughifugal force or volume change.

Structural composition

Core flow parts:

Impeller and volute: made of high-purity alumina silicon carbide ceramics, with nano-crystal sintering treatment on the surface, the corrosion resistance is more than 10 times that of stainless steel.

Seal system: the ceramic seal ring cooperates with the shaft sleeve, the friction coefficient is as low as 0.05, the clearance accuracy reaches 001mm, and leakage is ensured.

Power and transmission parts:

Drive shaft: the zirconia ceramic shaft is plated with coating, and the wear resistance life is 8 times that of the stainless steel shaft.

Bearing: full ceramic bearing (silicon nitride ball alum ring), suitable for the environment of -200℃~1200℃, no lubrication required.

Supporting and auxiliary structure

Pump body shell: ductile iron or engineering plastic lined with ceramic coating, which absorbs vibration and reduces noise by 20dB.

Pl and cylinder (volumetric): the zirconia ceramic plunger is precisely matched with the pump liner, and the surface micro-porous structure achieves self-lubrication.

Working principle

Centrifugal ceramic pump:

The motor drives the ceramic impeller to rotate at a high speed (140-2900 rpm), and the liquid obtains kinetic energy under the action of centrifugal force, which is converted into pressure energy through the volute and discharged

The low surface energy design of the impeller surface (contact angle >110°) reduces the blockage of viscous medium, and the hydraulic efficiency reaches than 75%.

Volumetric ceramic pump:

The reciprocating motion of the plunger changes the volume of the pump cavity during the suction stroke, the plunger moves backward to form a negative pressure, and the inlet valve opens to suck liquid; during the discharge stroke, the plunger moves forward increase the pressure, and the outlet valve opens to discharge liquid.

Ceramic diaphragm or gear achieve a metering accuracy of ±0.5, and the particle retention capability is below 5μm.