News

LATEST NEWS

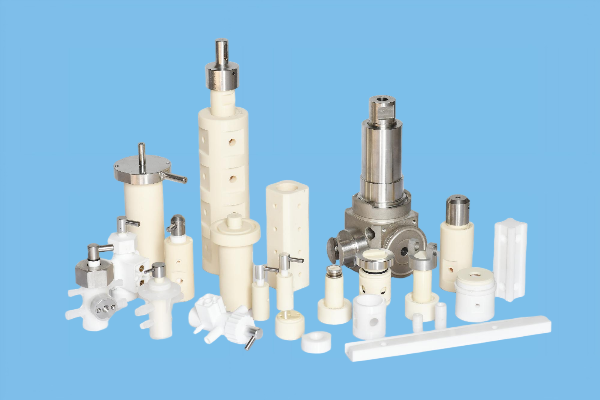

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

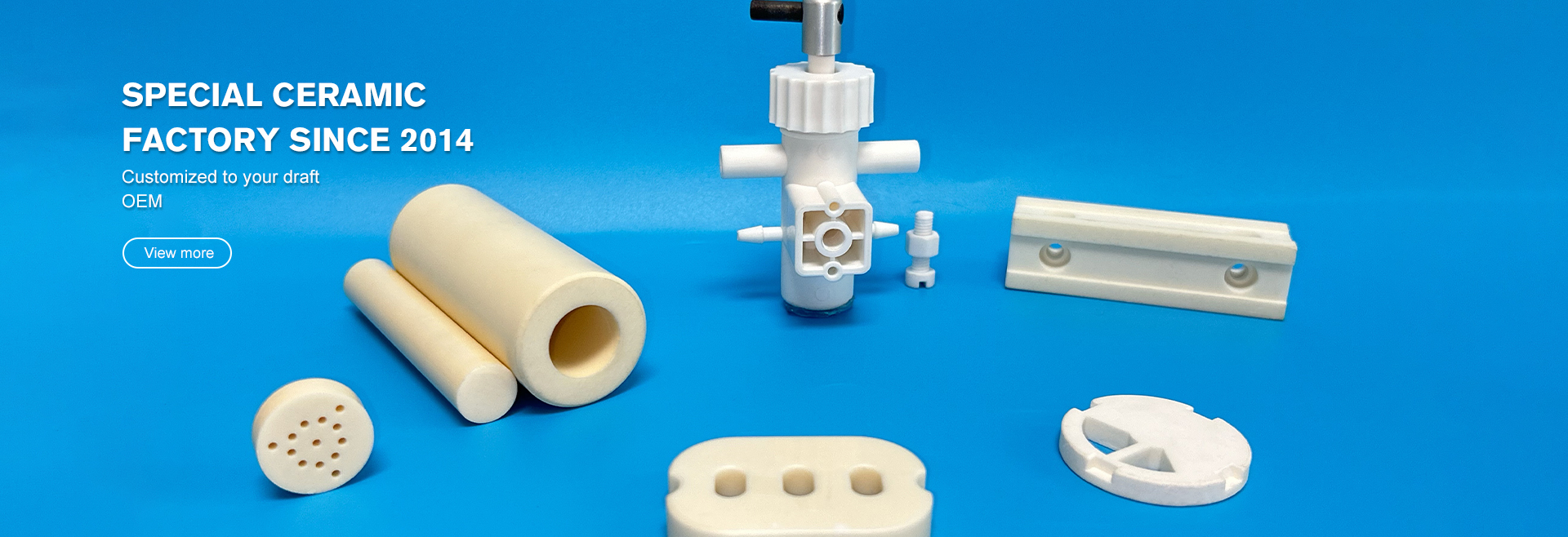

Ceramic and stainless steel differences of three-cylinder plunger pump

2026-02-01 14:37:14 View:4The difference between ceramic and stainless steel plungers in a three-cylinder plunger pump

a three-cylinder plunger pump, ceramic and stainless steel plungers are two mainstream materials, and they show significant differences in performance, application scenarios, and cost.

Differences Comparison

Characteristics Ceramic Plunger Stainless Steel Plunger

Main Material Usually zirconia (ZrO₂) or 9% high-alumina porcelain, some are silicon nitride (Si₃N₄) Common stainless steel grades such as 304, 316 or 3Cr13 are usedAbrasion resistance Excellent, with a hardness far exceeding that of metal, the abrasion resistance is more 5-10 times that of metal plungers, suitable for high-frequency, long-term operation

2 Good, but far inferior to ceramics. plating or laser treatment can improve abrasion resistance, but it is still prone to wearCorrosion resistance Outstanding, almost completely inert to acids, alkalis, salt solutions, and organic solvents, suitable for strong corrosive environments such as chemical, pharmaceutical, and sewage treatment Good, 316 steel has strong corrosion resistance, but it can still be corroded by strong acids, strong alkalis, or high-salt media in the long term

3High-temperature resistance Excellent, the melting point of zirconia ceramic can reach 1500°C, with good thermal stability, and is not to deform at high temperatures Good, but long-term exposure to high temperatures may affect mechanical properties and dimensional stabilitySelf-lubricating Have, ceramic materials (such as silicon nitride) have a micro-porous structure on the surface, which can form a self-lubricating film to reduce friction

4 No self-lubricating property, relying on external lubricating oil or seals, and poor lubrication can easily lead to wear and leakageService life ificantly longer, with a life span of up to 5-10 times that of metal plungers under harsh working conditions, especially in high-pressure, high- environments Shorter, especially in situations with poor water quality, high pressure, or corrosive media, the life span is significantly lower than that of ceramic plungers High, raw materials and manufacturing processes are complex, and the initial purchase cost is 2-3 times or even higher than that of stainless steel

5 Lower, the material cost and processing cost are relatively low, and the cost performance is highMaintainability Poor, once damaged, usually needs to be replaced as a whole, and the maintenance cost is high

6 Better, relatively easy to repair or replace after damage, and spare are easier to obtainApplication scenarios High-pressure cleaning (industrial grade), chemical metering pumps, medical equipment, lithium battery manufacturing, sewage treatment, electronic, etc., for occasions with high precision, cleanliness, life, and corrosion resistance requirements

Household and light commercial high-pressure cleaners, ordinary industrial pumps, pressure below 300 kg scenarios

Choose ceramic plungers: If your three-cylinder plunger pump is used in high-, high-wear, strong corrosion or high-cleanness industrial environments, and you pursue ultra-long life and low maintenance frequency, ceramic plung are a better choice, although the initial investment is higher.

Choose stainless steel plungers: If it is used in ordinary household, small commercial or requirements are not high (such as below 120 kg) cleaning scenarios, and you are sensitive to cost, stainless steel plungers are an economical

Note: Poor water quality and high sand content will significantly shorten the life of plungers of any material, it is recommended to use filtering devices in combination