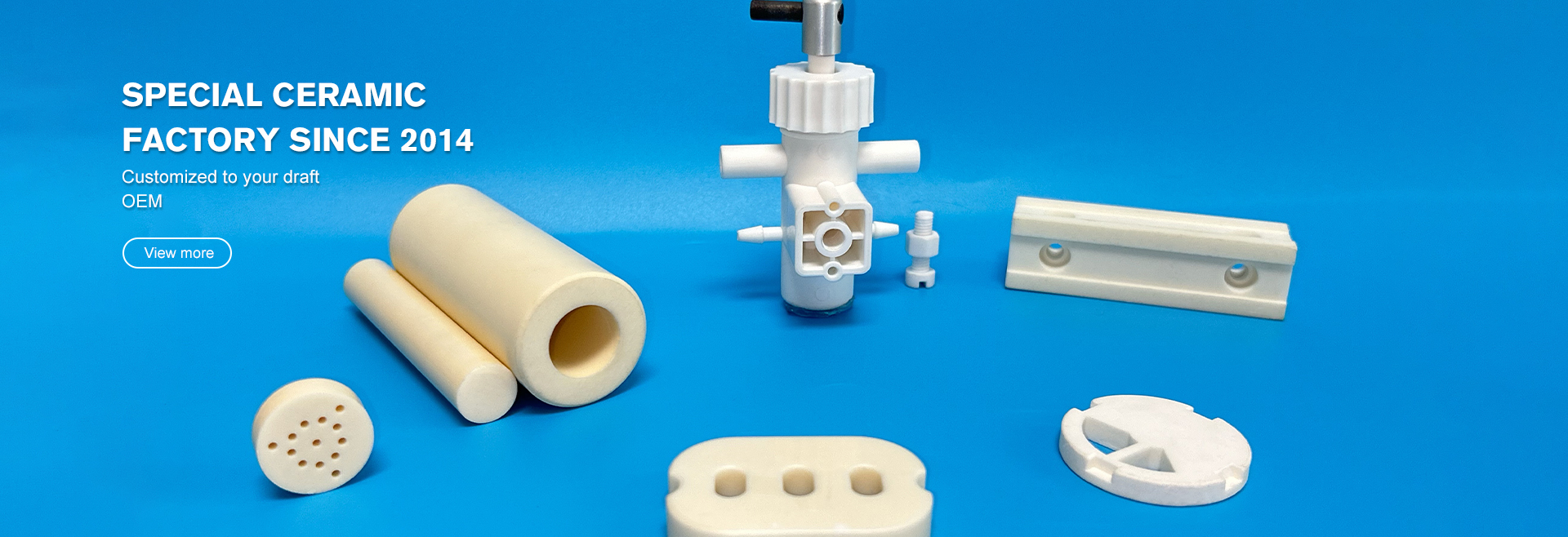

Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Ceramic plunger pump

HOMECeramic plunger pump

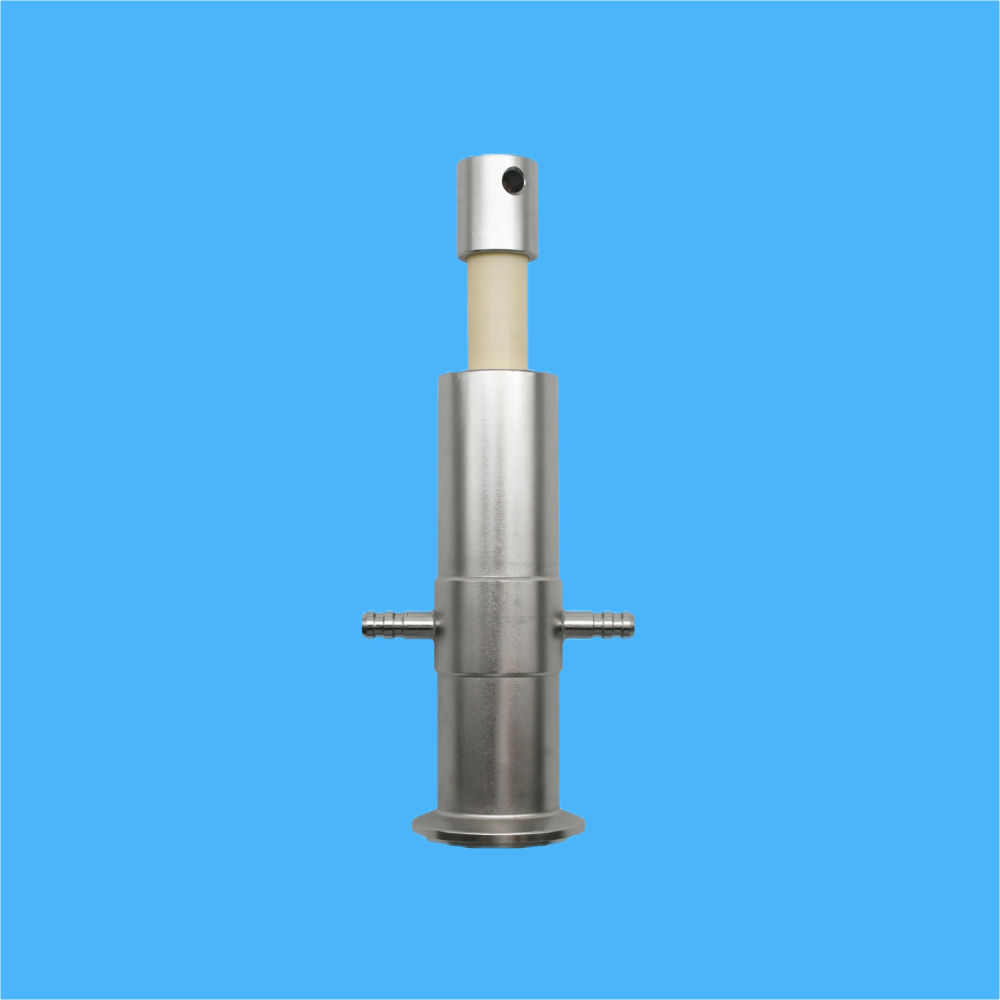

Column chromatography ceramic pump

Column chromatography ceramic pump

The main function of the chromatography ceramic pump is to provide the mobile phase and inject the sample solution into the chromatographic column for separation at a certain flow rate.

The working principle of the column chromatography ceramic pump includes pressure regulation, flow rate stability, and mixing. By adjusting the pressure before the column, the flow rate and pressure of the solvent can be controlled to ensure that the sample is properly separated in the chromatographic column. can provide a stable flow rate to ensure that the mobile phase flows evenly in the chromatographic column, thereby ensuring the accuracy and reproducibility of the separation. It also has solvent mixing function, which can mix different solvents according to the preset ratio to meet the separation needs of complex samples.

The common faults of the chromatography ceramic include the following:

Low output pressure: Check whether the hydraulic oil is sufficient. If the oil is insufficient, hydraulic oil should be added in time; check whether the overflow is working normally. If not, it needs to be cleaned or replaced; check whether the hydraulic cylinder seal is worn or damaged. If worn or damaged, the seal needs to be; check whether the hydraulic pump is damaged or worn. If damaged or worn, the hydraulic pump needs to be replaced.

Insufficient output flow: Check whether the quality of hydraulic oil meets the requirements. If the oil quality is not good, hydraulic oil needs to be replaced; check whether there is a leakage problem in the hydraulic system. If there is leakage problem, it needs to be repaired or replaced.

Poor sealing of the chromatography ceramic pump: Check whether the fit between the piston and the piston is tight. If not tight, the piston needs to be re-installed; check whether there are scratches or wear on the piston surface. If there are scratches or wear it needs to be repaired or replaced; check whether the piston spring is deformed or broken. If it is deformed or broken, the piston spring needs to be replaced.

Piston jamming: Check whether there is a blockage problem in the hydraulic system. If there is a blockage problem, it needs to be cleaned; check whether there is foreign matter attached to the piston surface. If there is any foreign matter attached, it needs to be cleaned.

Leakage problem: The chromatography ceramic pump have a leakage problem during use. The main reason is that the sealing parts are aging or damaged. The solution is to replace the sealing parts to ensure good sealing performance.

Noise: The chromatography ceramic pump may produce noise during operation. The main reason is that the pump is not installed stably or the friction between the piston and the cavity is too large. The solution is to adjust the installation position of the pump to ensure stability and add a proper amount of lubricant to reduce friction.

Unstable: The chromatography ceramic pump may exhibit unstable behavior during operation. The main reason is that the fit between the piston and the pump cavity is poor or the piston is. The solution is to check the fit between the piston and the pump cavity and replace the fitting parts if necessary to ensure proper tightness.

The above are common faults solutions for the ceramic pump. When using the chromatography ceramic pump, regular maintenance and inspection should be performed to discover and solve these problems in time and ensure the normal operation of chromatography ceramic pump.

Chromatography ceramic pump application

1. Chemical analysis: It can be used for chemical analysis, such as the separation and identification organic compounds, biomolecules, etc.

2. Drug research and development: It can be used for drug research and development, such as pharmacokinetics toxicology, and purification process, etc.

3. Food safety: It can be used for food safety testing, such as the detection and separation of pestic residues, food additives, heavy metals, etc.

4. Environmental monitoring: It can be used for environmental monitoring, such as the detection and separation ofants in air, water, soil, etc.

5. Biomanufacturing: It can be used for the purification and separation in the process of biufacturing, such as the purification of proteins, antibodies, etc.

6. Forensic medicine: It can be used for the separation and detection of po and drugs in forensic medicine.