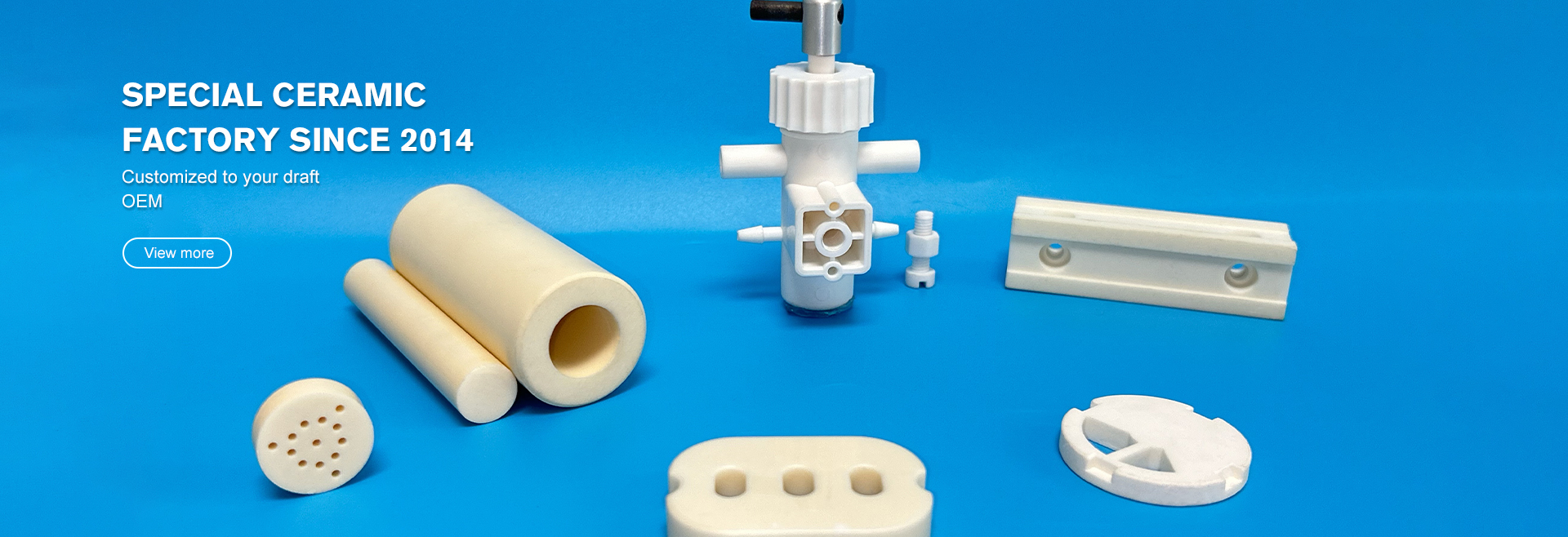

Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Ceramic plunger pump

HOMECeramic plunger pump

Ceramic analysis pump

Ceramic analysis pump

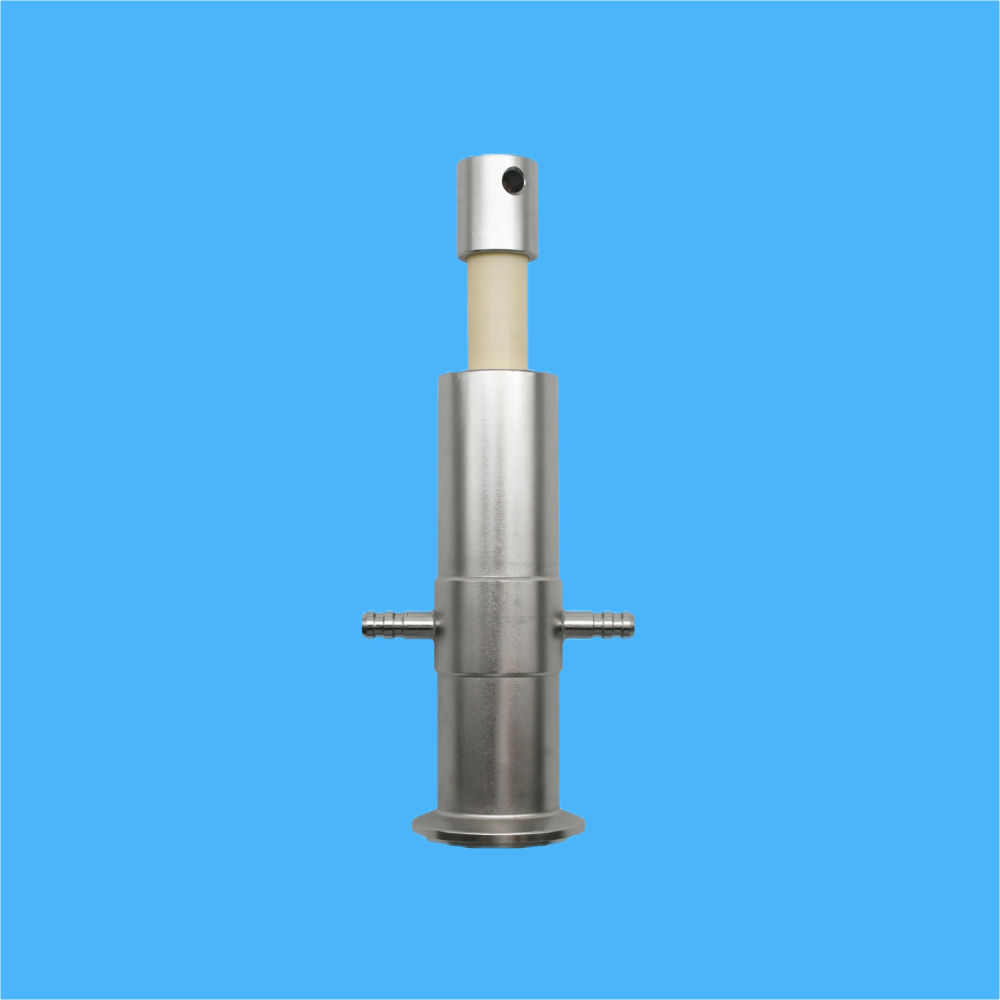

Dewatering pump, ultrafiltration pump is usually used for liquid filtration and dewatering treatment, and the ceramic cavity is often used as internal structure of the pump because of its high temperature resistance and corrosion resistance. The combination of the three can improve the efficiency and stability of the pump. The specific product selection and need to be combined with the actual needs.

Dewatering pump_Ultrafiltration pump_Ceramic cavity has the following features:

Adopt-performance technical ceramic materials, which has high hardness, wear resistance, high temperature resistance, corrosion resistance and other properties. Ensure reliable material performance.

The inner cavity surface is with fluid structure, no dead angle, groove. The inner cavity surface and piston surface are processed to mirror surface by advanced high-precision internal and external round grinding bed, and outer surface is vibrating polished, which is convenient for cleaning and disinfection.

The pump body structure is made of 316L stainless steel with seal, is convenient to disassemble.

Dehydration pump_ultrafiltration pump_ceramic cavity with high precision metering accuracy, simple operation, easy to disassemble and install disinfection and cleaning, a variety of specifications are available for filling 0-1ml, using the characteristics of ceramic acid and alkali resistance, high temperature resistance and wear, the ceramic pump produced by the volume can be stable and lasting, cold and hot, not easy to jam, the service life is greatly improved compared with stainless steel pump, in with GMP standards.

Model Piston diameter Liquid volume

JC-05 D4.76MM 0-0.4ML

JC-06 D6.35MM 0-0.7ML

JC-10 D9.94MM 0-1.2ML

Dehydration pump _ ultrafiltration pump _ ceramic cavity common faults include the following:

Low output pressure Check if the hydraulic oil is sufficient, if the oil is insufficient, the hydraulic oil should be added in time; check whether the overflow valve is working normally, if not, it needs to be cleaned or replaced; check whether the hydraulic cylinder seal is worn or damaged, if worn or damaged, the seal needs to be replaced; check whether the hydraulic pump is or worn, if damaged or worn, the hydraulic pump needs to be replaced.

Insufficient output flow: Check whether the quality of the hydraulic oil meets the requirements, if oil quality is not good, the hydraulic oil needs to be replaced; check whether there is a leakage problem in the hydraulic system, if there is a leakage problem, it needs to repaired or replaced.

Dehydration pump _ ultrafiltration pump _ ceramic cavity seal is not good: Check whether the fit between the piston and the piston hole tight, if not tight, the piston needs to be re-installed; check whether there are scratches or wear on the piston surface, if there are scratches or wear, needs to be repaired or replaced piston; check whether the piston spring is deformed or broken, if it is deformed or broken, it needs to be replaced piston spring.

Piston jammed: Check whether there is a blockage problem in the hydraulic system, if there is a blockage problem, it needs to be cleaned; check whether there debris attached to the piston surface, if there is debris attached, it needs to be cleaned.

Leakage problem: The dehydration pump _ ultrafiltration pump ceramic cavity may have leakage problems during use, the main reason is that the seal is aging or damaged. The solution is to replace the seal to ensure good sealing performance.

ise is too high: The dehydration pump _ ultrafiltration pump _ ceramic cavity may produce noise during operation, the main reason is that the pump is installed unstably or friction between the piston and the pump cavity is too large. The solution is to adjust the installation position of the pump to ensure stability, and add a proper amount of lubricant reduce friction.

Unstable operation: The dehydration pump _ ultrafiltration pump _ ceramic cavity may be unstable during operation, the main reason is that the fit between piston and the pump cavity is not good or the piston is loose. The solution is to check the fit between the piston and the pump cavity, and replace the fit when necessary to ensure that the tightness is appropriate.

The above are common faults and solutions of dehydration pump _ ultrafiltration pump _ ceramic cavity. When using theration pump _ ultrafiltration pump _ ceramic cavity, it should be regularly maintained and checked, so as to discover and solve these problems in time, and ensure the normal operation of dehydration pump _ ultrafiltration pump _ ceramic cavity.

Dehydration pump _ ultrafiltration pump _ ceramic cavity application

1. Chemical analysis: It can be used for chemical analysis such as the separation and identification of organic compounds, biomolecules, etc.

2. Drug development: It can be used for drug development, such as pharmacinetics, toxicology, and purification processes.

3. Food safety: It can be used for food safety testing, such as the detection and separation ofide residues, food additives, heavy metals, etc.

4. Environmental monitoring: It can be used for environmental monitoring, such as the detection and separation pollutants in air, water, and soil.

5. Biomanufacturing: It can be used for the purification and separation in the process of biomanuring, such as the purification of proteins, antibodies, etc.

6. Forensic medicine: It can be used for the separation and detection of poisons drugs in forensic medicine.