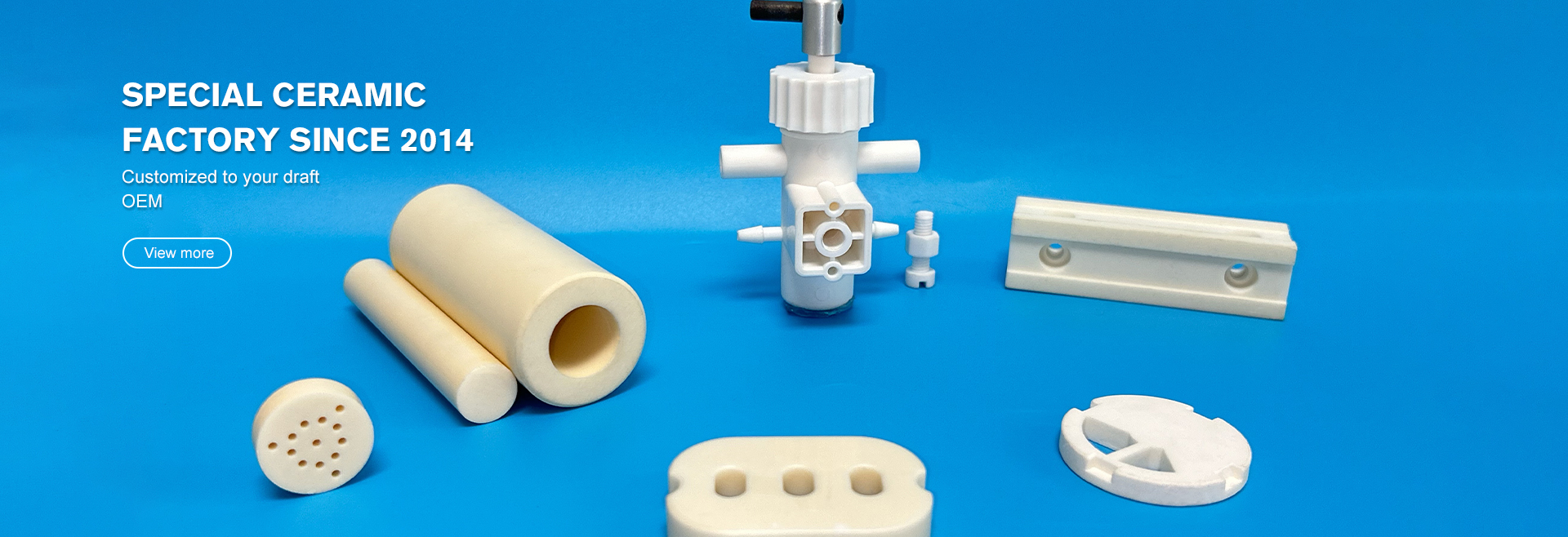

Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

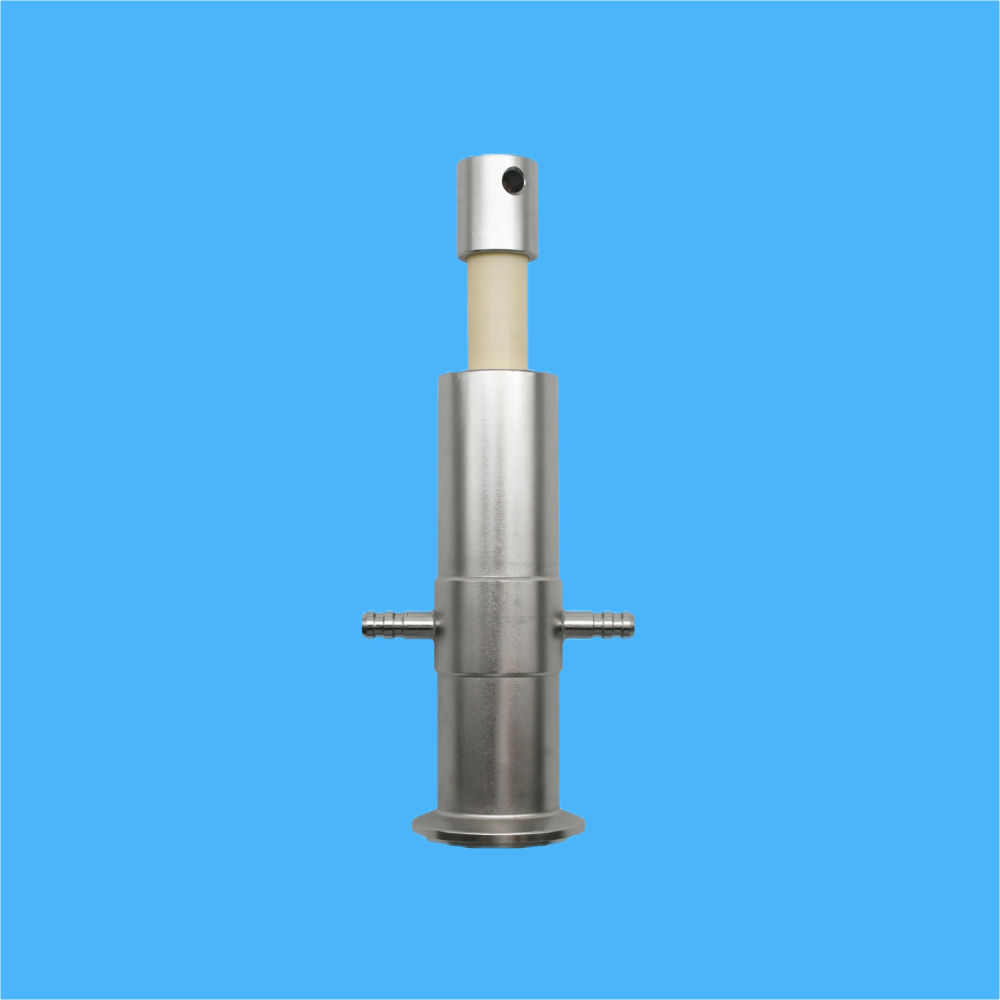

Ceramic plunger pump

HOMECeramic plunger pump

Ceramic pump;chemical injection pump;metering pump.

Ceramic pump;chemical injection pump;metering pump

Ceramic pumps, chemical injection pumps, metering pumps, are key components of dispensing equipment, featuring high precision, high stability, etc. The injection of the dispensing machine is an important part of the entire dispensing system. Together, they ensure the accuracy and safety of dispensing.

Ceramic pump; chemical metering pump; model of the metering pump:

Model Piston diameter Liquid volume

JC-16 D16MM 0-3ML

JC-25 D25MM 0-10ML

JC-40 D40MM 0-20ML

Ceramic pumps; chemical metering pumps; typical applications:

Biological industry: diagnostic reagents, nucleic acid, vaccines, anticoagulant for blood collection tubes, gels, oral DMA analyzers, dispensing, test tube filling, addition and spraying of blood sample collection reagents and drug solution production, etc.

Energy industry: button, cylindrical batteries, capacitors, polymer batteries, power batteries, lead-acid, zinc-air batteries quantitative addition of liquid and battery glove boxes, automatic/semi-automatic filling machines and other equipment manufacturers.

Electronic industry: AF coating, silver glue, VC, heat pipe, optical lens, microelectronics, semiconductor etching and cleaning, LED chip dot glue packaging, LCD precision spraying, micro dot glue machine and other supporting equipment.

Chemical industry: COD water pollution detection reagents,ic acid filling, hydrochloric acid, nitric acid, boric acid, borax, fungicide, ink, paper strength enhancer, dye quantitative addition, agent addition, slaked lime addition, etc.

Daily chemical industry: emulsion, essential oil, mascara, cleanser, cosmetics, skin cream, hair dye, acid, addition of cosmetics pigments, humidity control and addition of fragrance filling.

Food industry: tomato paste, milk, yogurt, cream, soda, fruit juice, wine condiments, mustard, condiments, honey, lard, fruit puree juice, pudding, yogurt food additives, flavors, edible oil dispensing, etc

Ceramic pump; working principle of chemical metering pump, dosing pump:

he ceramic filling metering pump consists of a ceramic pump body, a rotary valve, a metering rod, stainless steel in and out liquid nozz and connecting parts, etc.

Working principle of the ceramic filling metering pump:

When the port of the rotary valve is aligned with the inlet, the downward motion of the ceramic column generates negative pressure and sucks up the liquid;

When the port of the rotary valve is aligned with the outlet, the upward linear motion of the column generates positive pressure and discharges the liquid.

Ceramic pump; chemical injection pump; assembly and connection with filling machine of metering pump.

Since the ceramic rod and ceramic sleeve are precision fit parts with small clearance and cannot be interchanged, the products are numbered before leaving the factory and should not interchanged during cleaning and assembly.

Before installation, ensure that all sealing parts are properly installed and there is no leakage.

It is necessary to eliminate the assembly with each part of the filler (assembly clearance causes changes in stroke, resulting in inaccurate metering) and to ensure the coaxiality of the moving parts (affecting the life and filling accuracy of the pump).