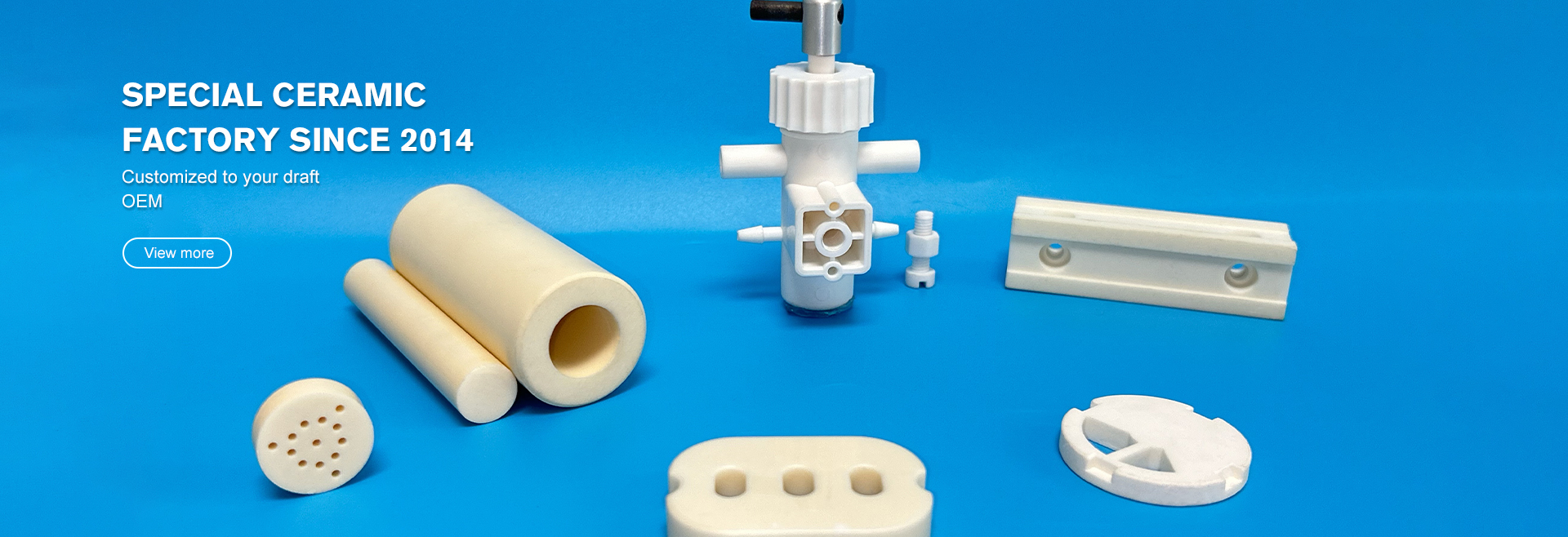

Products

LATEST NEWS

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

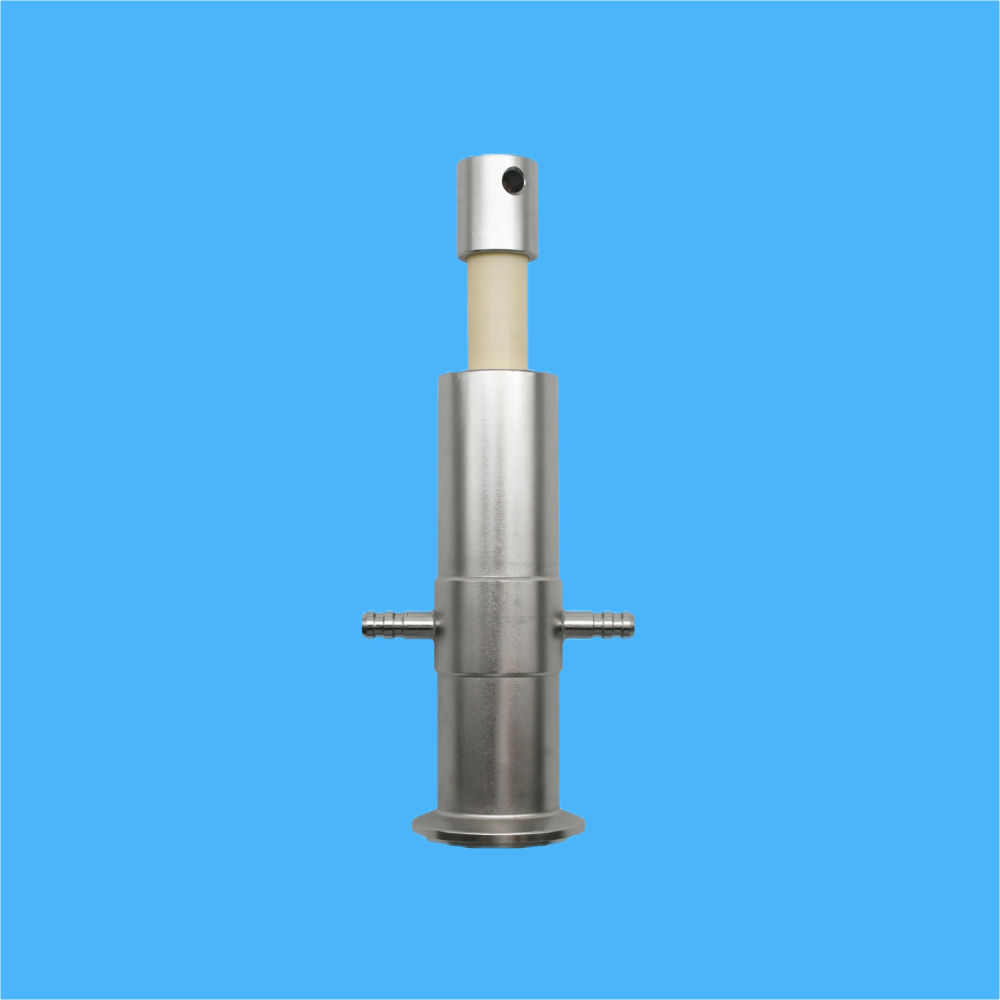

Ceramic plunger pump

HOMECeramic plunger pump

Microliter ceramic pump

The micro-liter ceramic pump is a type of micro-pump made of ceramic materials, featuring high precision, high corrosion resistance, and long lifespan. It is widely used in medical, chemical, biological, and other fields for liquid transmission and micro-control.

The micro-liter ceramic pump has the following features:

It adopts high-performance technical ceramic materials, which are hard, wear-resistant, heat-resistant, and corrosion-resistant. The material ensures reliable performance.

The micro-holes obtained by unique processing methods on the plunger working surface have self-lubricating properties, changing the mechanism of sliding friction and lubrication of traditional plunger pumps.

The inner cavity surface adopts a fluid structure with no dead corners or grooves. The inner cavity surface and the plunger surface are machined to a mirror finish by advanced high-precision internal and external grinding machines, and the outer surface is vibrating polished, which is convenient for cleaning and disinfection.

The pump body structure uses 316L stainless steel with seals, which is convenient for disassembly.

This type of product has undergone corrosion resistance and pH safety performance testing, and its indicators have reached the level of foreign similar products.

The appearance and size can be designed and processed according to the user's needs.

1. Technical indicators of the micro-liter ceramic pump

The micro-liter ceramic pump has high precision metering accuracy, simple operation, easy disassembly, installation, and disinfection and cleaning features. Various specifications are available for filling 1-1ml. Taking advantage of the ceramic's resistance to acid, alkali, high temperature, and wear, the ceramic pump produced can maintain stable and persistent filling, which is not easy to jam when cold or hot. Compared with stainless steel pumps, the service life is greatly improved and meets GMP standards.

Filling range: 0.2-50ML;

Operating temperature: 1~80℃;

Filling precision standard: when the filling amount is less than 2ML, the upper and lower deviations shall not exceed ±1%; when the filling amount is greater than 2ML, the upper and lower deviations shall not exceed ±0.5%.

Our company's ceramic metering pumps cover most of the market specifications and can also be customized according to your needs.

The structure of the micro-liter ceramic pump:

The micro-liter ceramic pump consists of a ceramic pump body, a rotary valve, a metering rod, stainless steel in-and-out fluid nozzles, and connecting parts.

Working principle of the ceramic filling metering pump:

When the port of the rotary valve is aligned