Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

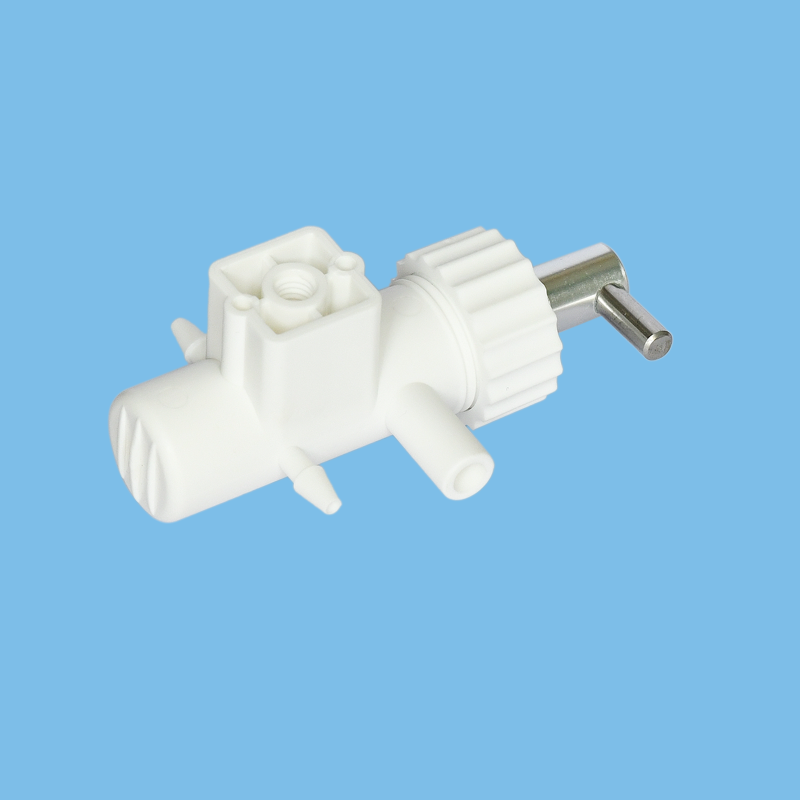

Food filling pump

HOMEFood filling pump

Electrolyte filling pump

The core of the electrolyte filling pump is corrosion resistance, high precision, and leak-proof, and the material selection directly determines its performance service life.

Main materials and applicable scenarios:

Fluorine plastic (PTFE/PVDF): resistant to strong acid and alk, it is the first choice for electrolyte delivery, especially suitable for electrolytes containing LiPF₆. For example, both RMD series and E-WIC MD/W series magnetic drive pumps adopt this material.

316L stainless steel: has good corrosion resistance, suitable for general medicine filling, but note that its long-term resistance may not be as good as fluorine plastic.

Ceramics (zirconia/alumina): high hardness, wear resistance, and strong chemical inertness, suitable for high-precision metering and corrosive liquids, such as lithium battery electrolyte filling pumps.

Other factors to consider when selecting a model

Temperature range: The working temperature of the electrolyte is usually between -20℃ and 100℃, and the material of the pump to adapt to this range.

Explosion-proof grade: The lithium battery workshop is an explosion-proof area, and the pump needs to reach Ex d IIB4 or above explosion-proof grade.

Seal structure: It is preferred to choose a fully enclosed isolation sleeve magnetic coupling design, which completely eliminates the dynamic sealing and achieves zero leakage.