Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

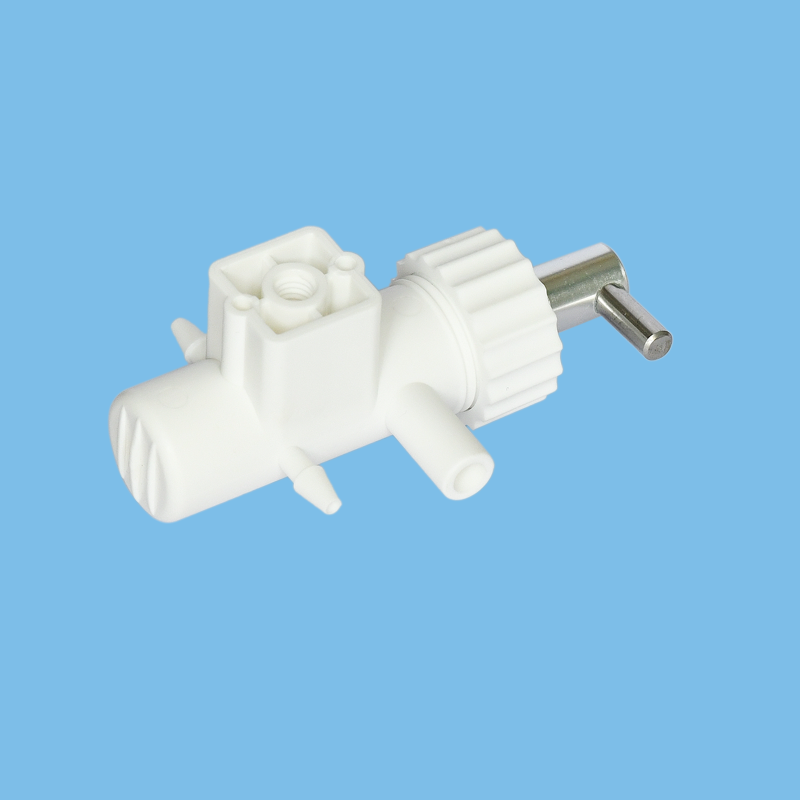

Food filling pump

HOMEFood filling pump

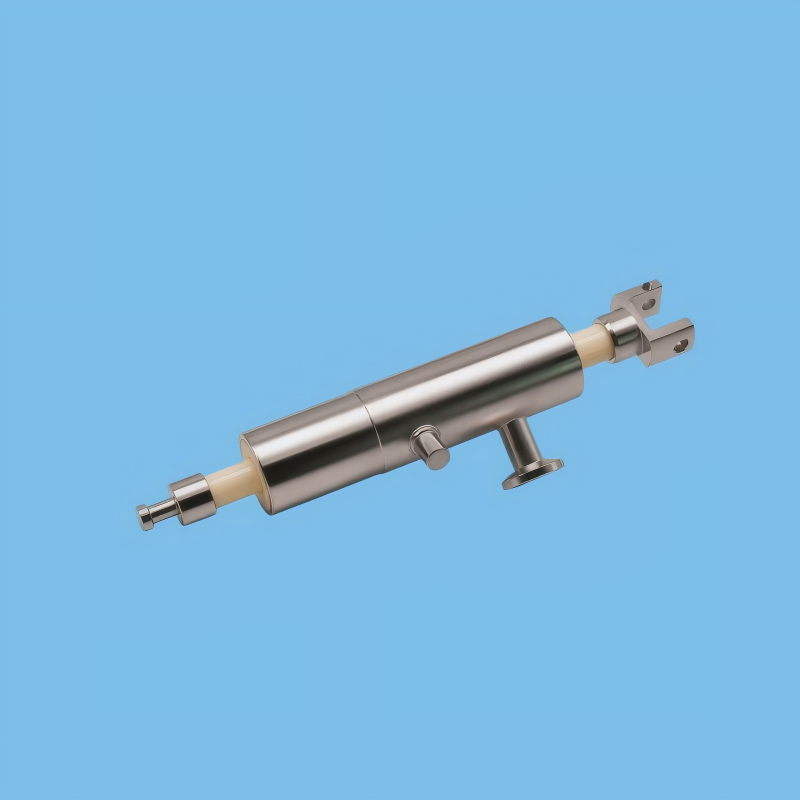

Medicine filling pump

The material selection for pharmaceutical filling pumps must strictly adhere to GMP regulations, with the core being corrosion resistance, sterility, and precision. key considerations are as follows:

1. Corrosion Resistance

Strong Acid/Base: Prefer 316L stainless steel, PTFE or fluoroplastics (such as F46).

Organic Solvents: Must be explosion-proof, with materials resistant to chemical corrosion (e.., fluororubber).

High Viscosity Drug Solutions: It is advisable to pair with a heating module to prevent material failure due to temperature changes.

2. Sterility Requirements

Contact Components: Must be able to be sterilized (e.g., ceramic pumps, silicone tubes), complying with G standards.

Sealability: Magnetic pumps or fully sealed designs prevent contamination.

3. Precision and Durability

High-Precision Filling:amic pumps or peristaltic pumps (±0.1% error).

Abrasion Resistance: Piston pumps require cast copper or ceramic materials.

4 Other Factors

Production Scale: Semi-automatic equipment can be chosen for small batches, while full automation lines are needed for large volumes.

Fluoroplastics and ceramic pumps have a higher cost, but they last longer.