News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Ceramic Plunger Pump Parts

2026-01-24 14:46:42 View:55Ceramic Plunger Pump Parts

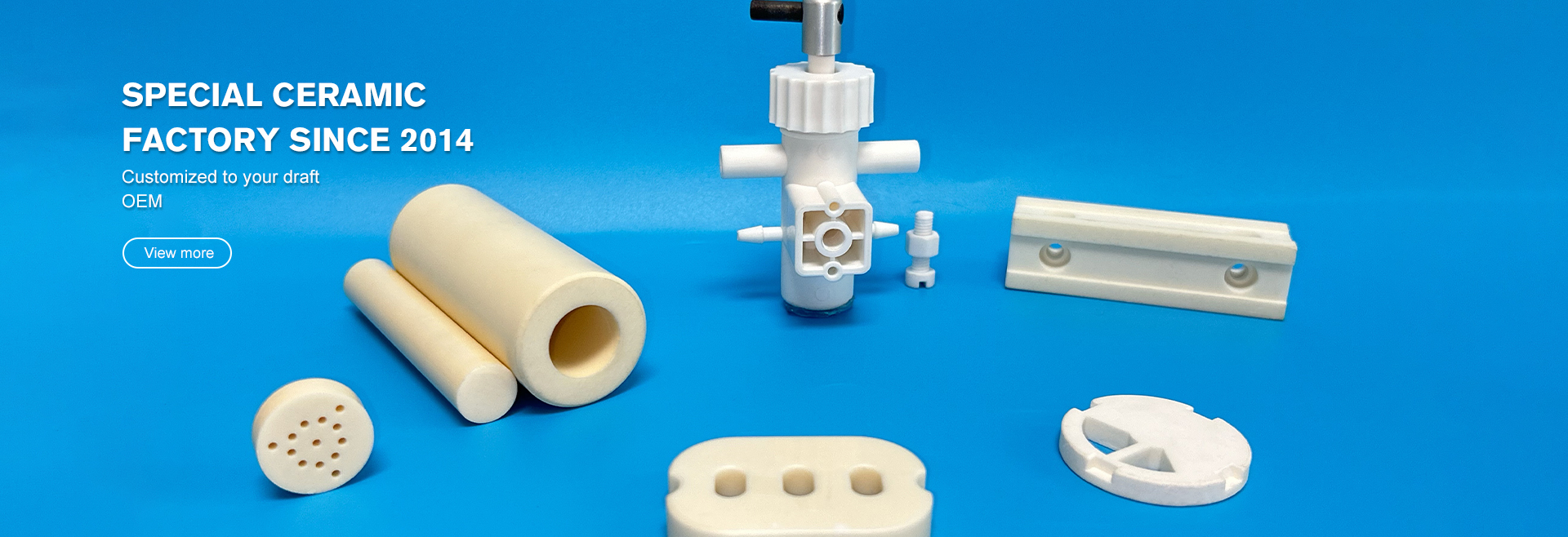

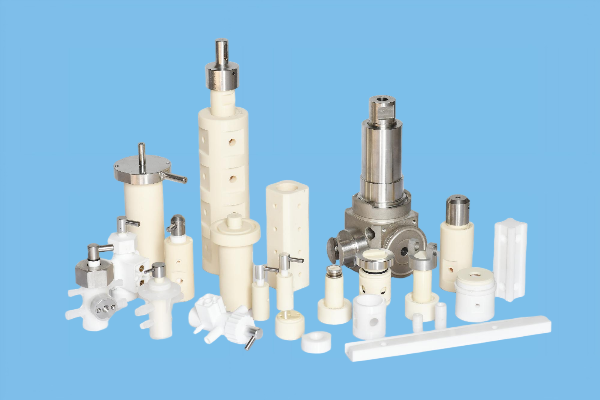

Ceramic plunger pump parts are the core components in a plunger pump, specifically to transport high-pressure fluids, resistant to wear and corrosion, and have a much longer lifespan than ordinary metal parts.

Core Parts

Ceramic Plunger: A wear-resistant shaft that directly contacts the fluid, with strong corrosion resistance.

Ceramic Sealing Ring: Prevents leakage of high-pressure fluid ensuring reliable sealing.

Ceramic Valve Disc/Seat: Controls the unidirectional flow of fluid, resistant to wear.

Cer Liner: Precision inner lining that cooperates with the plunger, with good wear resistance.

Price Reference

Basic parts (such as sealing rings, discs): From tens to hundreds of yuan.

Complete set of ceramic plunger components: From hundreds to thousands of yuan.

High-end or brand parts: Over a thousand yuan.

Selection Tips

Confirm the model number: First confirm the model and specifications of the pump.

Pay attention to the material: Prefer zirconia ceramic, which is wear-resistant and corrosion-resistant.

Choose the channel: It is recommended find a professional industrial platform or manufacturer to ensure compatibility.

Precautions

Installation precision: Ceramic parts have high installation requirements and need to be operated according the specifications.

Regular maintenance: Regularly check the sealing rings and valve discs and replace them in time.

Compatibility: Ensure that the match the model and pressure grade of the pump.

If you need more specific models or parameters, you can tell me the brand of your pump or the usage scenario, which help you further filter.