News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Ceramic slurry plunger pump

2026-01-23 08:16:54 View:58Ceramic Slurry Plunger Pump

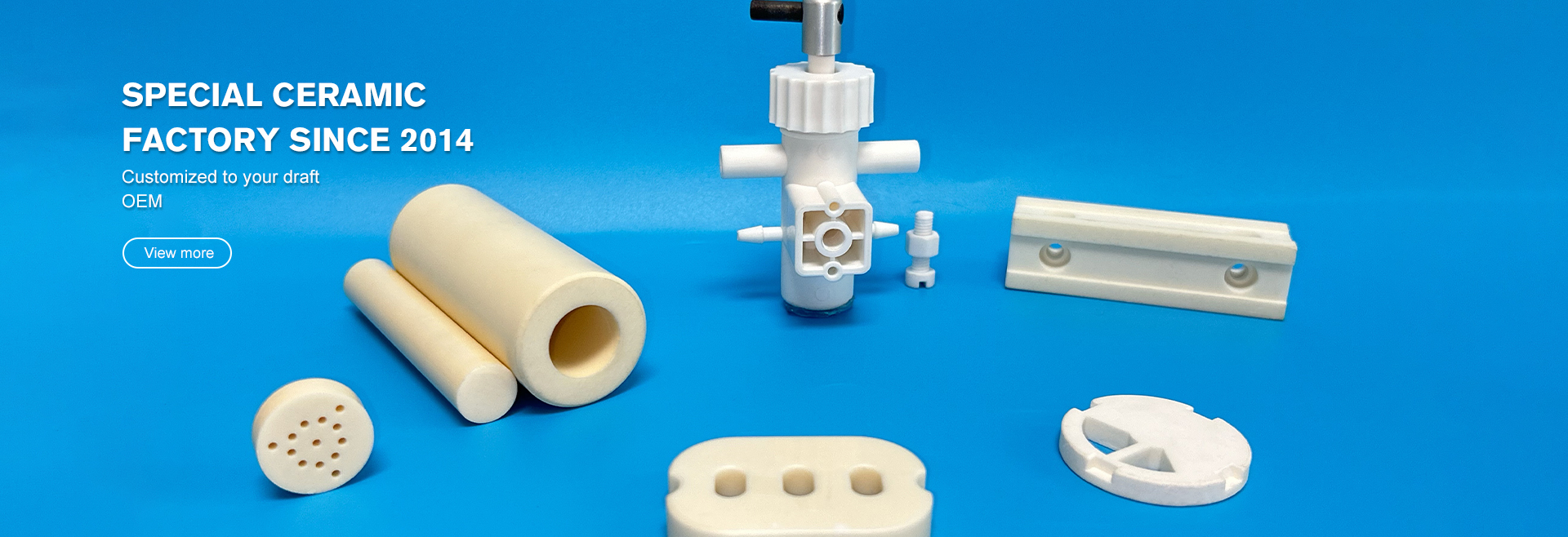

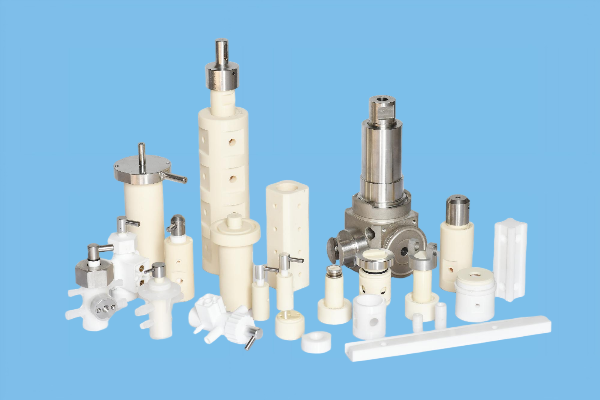

The ceramic plunger slurry pump is a hydraulic-driven pump that an alumina ceramic plunger, specially designed for high-pressure transportation of high-viscosity media such as slurry and mud, featuring strong abrasion resistance and long service. It is widely used in the ceramic, mining, environmental protection, and other fields.

Working Principle and Technical Parameters

Core Principle: The hydraulic system is used to push the ceramic plunger to perform reciprocating motion, changing the volume of the sealed cavity to achieve suction and pressure of the slurry. When theunger is pulled out, negative pressure is formed to suck in the slurry; when it is pushed in, the slurry is compressed and discharged. The check valve controls the flow, and the micro-hole structure provides self-lubrication.

Key Parameters:

Flow rate range: 0.1–6m³/h (e.g., YB300 type with a flow rate of 60m³/h).

Pressure: 1.0–6.0MPa (up to 6.0MPa), adjustable constant pressure.

Material: The plunger isina ceramic (hardness HRA88-91), and the pump body is mostly cast iron.

Applicable medium: Slurry and mud with density≤2.5kg/m³ and viscosity ≤20000cps.

Application Fields and Advantages

Core Application:

Ceramic industry: Transport of glaze and green body slurry (working pressure 1.8–2.0MPa).

Miningurgy: Processing of tailings slurry (pressure 4.0–6.0MPa, conveying distance >500 meters).

Environment protection field: Feed for filter press, processing of high-concentration sludge (density 2.3–2.5kg/m³).

Core Advantages:

Abrasion resistance: The service life of the ceramic plunger is 6–8 times longer than that of the metal plunger, downtime for maintenance.

High efficiency and energy saving: When pressure ≥5MPa, the motor power is 1–2 models smaller than other.

Stability: The double-cylinder synchronous design ensures pressure fluctuation ≤0.3MPa, and supports frequency conversion regulation.

Brand Model Comparison and Purchase Guide

Mainstream Brands and Models:

Juchang Ceramic Pumps: Flow rate 0.1–60³/h, pressure 1.0–6.0MPa, suitable for ceramics and mining.

Purchase Suggestions:

Priority should be given to the combination of hydraulic drive and ceramic plunger to ensure corrosion resistance.

Select according to the medium viscosity: High viscosity (such sludge) requires pressure ≥4MPa, and low viscosity (such as glaze) can select 1.5–2.0MPa.Ceramic slurry plunger pump