Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

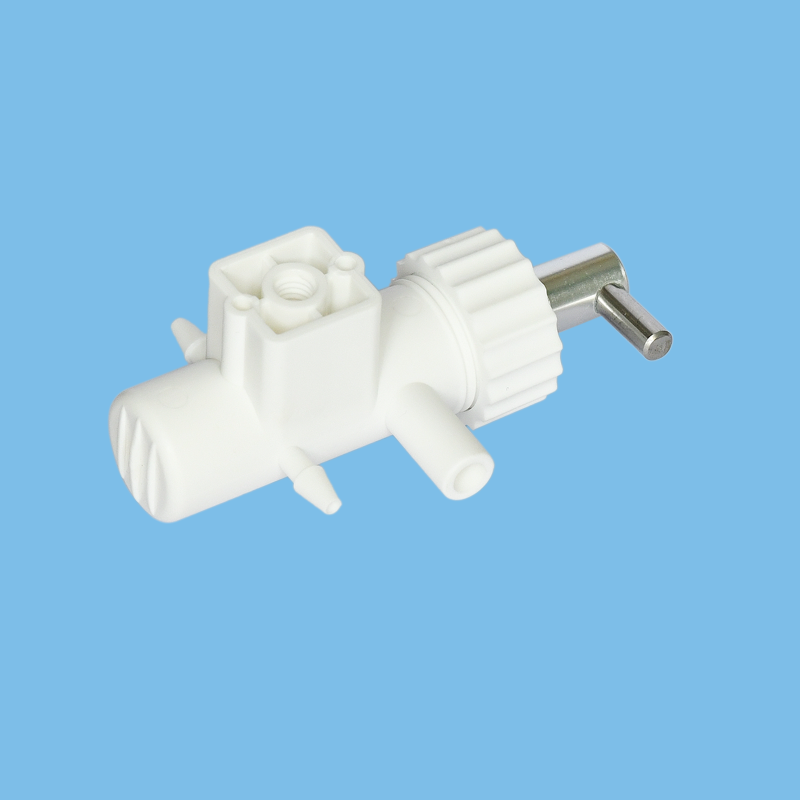

Food filling pump

HOMEFood filling pump

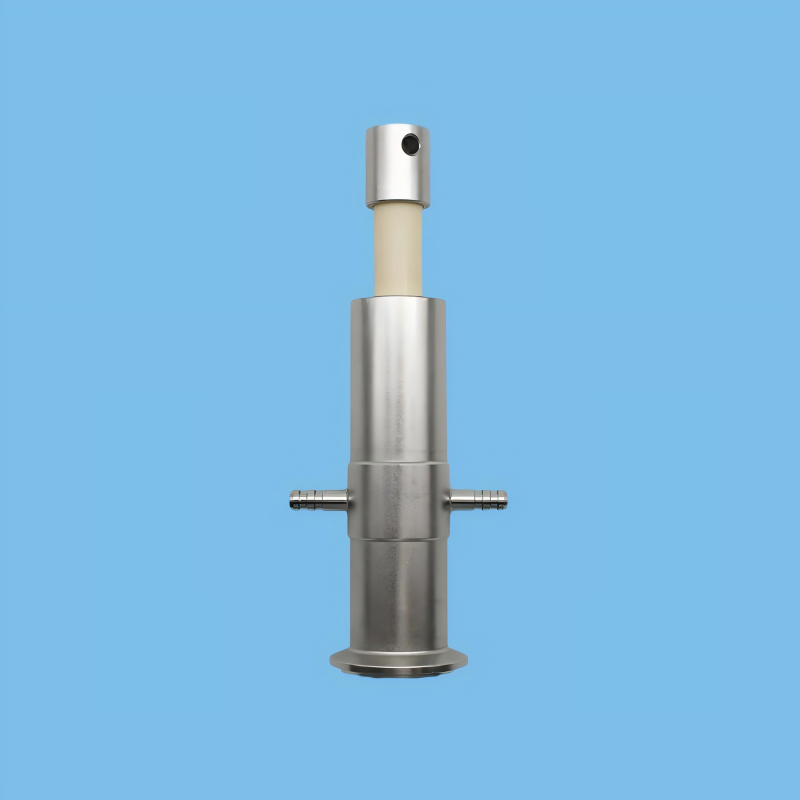

Chemical corrosion ceramic pump

Chemical corrosion resistant ceramic pumps are industrial pumps specially designed for corrosive media such as strong acids and alkalis. The core components are made of ceramic such as silicon carbide and silicon nitride, which have super strong corrosion resistance, high temperature resistance and wear resistance. The service life is far longer than metal pumps and the maintenance is lower.

Core Advantages

Corrosion resistance: Can withstand strong corrosive media such as concentrated sulfuric, hydrofluoric acid, aqua regia, etc., with a lifespan several times longer than metal pumps.

High temperature resistance: Can operate at temperatures above1200℃, suitable for high-temperature fluid transportation.

Low wear: With extremely high hardness, the wear rate is reduced by more than 90 when transporting media containing particles.

High purity: The surface is smooth and pore-free, does not contaminate the fluid, and is suitable for industries with high requirements such as pharmaceuticals and semiconductors.

Typical Applications

Chemicals: Transporting strong corrosive liquids such as concentrated sulfuric acid and hydroflu acid.

Oil: With corrosion resistance and high temperature resistance, it is suitable for harsh environments.

Metal/Mining: Good wear resistance, for transporting slurry and tailings.

Pharmaceuticals/Semiconductors: High purity, ensuring the purity of the fluid.

How to Choose the Chemical Corrosion Ceramic Pump

When choosing a chemical corrosion ceramic pump, it is necessary to evaluate the medium characteristics and working conditions comprehensively. The following are key selection points

1. Corrosion resistance selection

Medium analysis: Define the type (such as strong acid, strong base, organic solvent) and concentration of the corros medium, zirconia ceramic has good corrosion resistance for most acids and alkalis, but specific corrosion such as hydrofluoric acid needs to be avoided.

Material matching:

Zirconia ceramic: Suitable for acid, alkali, and salt solutions, with excellent corrosion resistance.

Silicon carbide ceramic: Withstands strong, strong alkalis, and high-temperature corrosion, suitable for chemical and metallurgical industries.

PTFE coating: For high purity requirements scenarios (such as pharmaceuticals, semiconors).

2. High temperature resistance selection

Temperature range: Zirconia ceramic can withstand temperatures up to 1200℃, and siliconide ceramic has a higher temperature resistance (≤1750℃).

Thermal stability: Avoid sudden temperature changes, and choose materials with good thermal shock (such as high-alumina ceramic).

3. Low wear selection

Particle content: For high wear conditions (such as slurry, tailings, choose silicon carbide ceramic or surface hardening treatment.

Surface treatment: Mirror machining can reduce particle attachment and extend life.

4. Industry applicability

hemicals/Oil: Give priority to silicon carbide ceramic, resistant to strong corrosion and high temperatures.

Pharmaceuticals/Semiconductors: zirconia or PTFE coating to ensure high purity.

Metallurgy: Silicon carbide ceramic is wear-resistant and suitable for high-temperature sl transportation.

5. Other parameters

Working pressure: For high-pressure scenarios (such as pressure filter), choose hydraulic ceramic plunger pump.

Custom demand: Support customization for small batches or special media.

Summary: The selection needs to focus on the medium characteristics, combined with industry needs to match the material process, to ensure long-term stable operation.