News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Working principle of ceramic plunger pump

2026-01-21 08:15:45 View:60Working principle of ceramic plunger pump

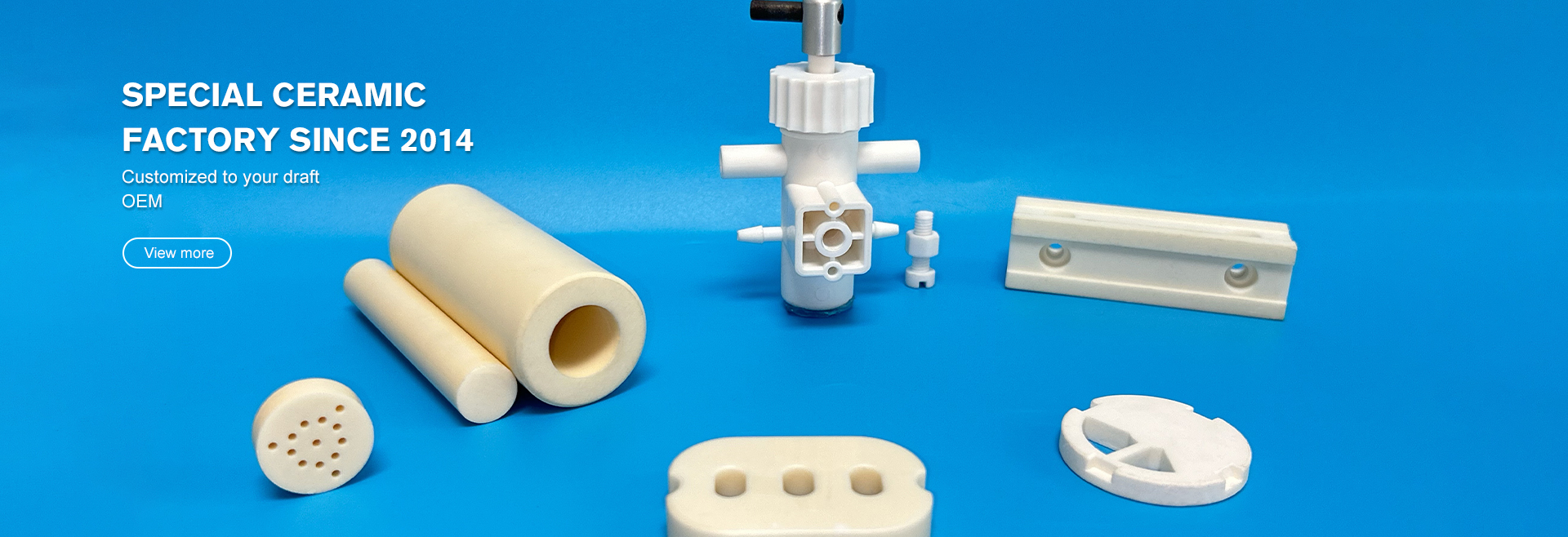

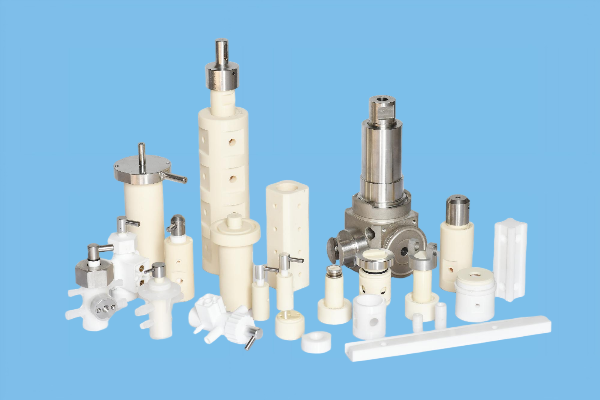

The ceramic plunger pump changes the volume of the sealed chamber by the reciprocating motion of the plunger in the pump cylinder, forming a pressure difference to fluid suction and discharge, and its core lies in the precise fit of the wear-resistant ceramic plunger.

Core Working Principle

The ceramic plunger pump utilizes the linear reciprocating motion of the plunger to periodically change the volume the pump cylinder chamber:

Intake Stage: The plunger moves backward, increasing the volume of the chamber to form a negative pressure, opening the inlet check, and allowing the fluid to be sucked in.

Discharge Stage: The plunger moves forward, reducing the volume of the chamber to generate high pressure, the outlet check valve, and forcibly discharging the fluid.

This process is continuously cycled through motor or hydraulic drive, achieving fluid transport.

Key Stural Components

Ceramic Plunger: The core component, made of oxide ceramic material, is hard and corrosion-resistant, adapting to high pressure ( to 80MPa) and media containing particles.

Pump Cylinder and Sealing Chamber: Precisely matched with the plunger, the of volume change determines the flow rate (max. 1500L/h).

Check Valve Group: Controls the unidirectional flow the fluid, preventing backflow.

Drive Mechanism: Crank, connecting rod, or swash plate system, converting rotational motion into the plunger' reciprocating motion.

Unique Advantages of Ceramic Plungers

Abrasion Resistance: The ceramic material's high hardness ensures a lifespan3-5 times longer than metal plungers, suitable for slurry and corrosive liquids.

High Precision: Small clearance (micron level) between m parts, flow control error <1%, suitable for metering scenarios.

Temperature Resistance: The working temperature can reach 450℃ adapting to high-temperature media.