News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Hydraulic ceramic piston pump

2026-01-22 08:18:30 View:63Hydraulic ceramic piston pump

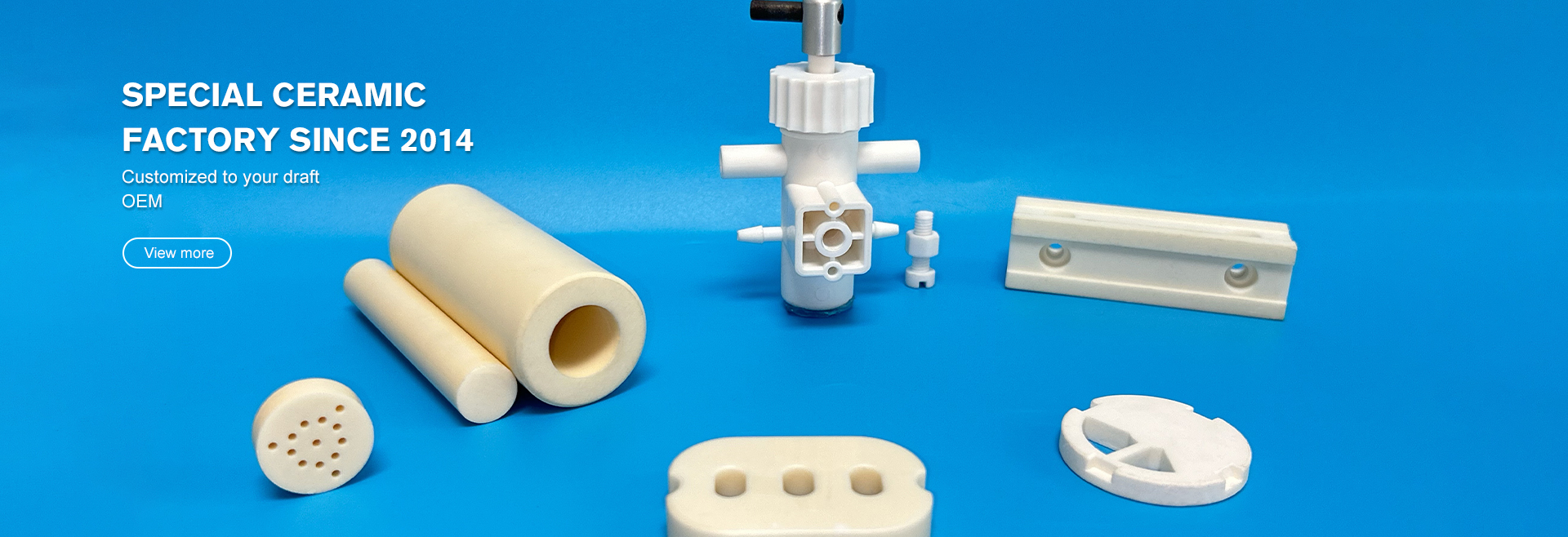

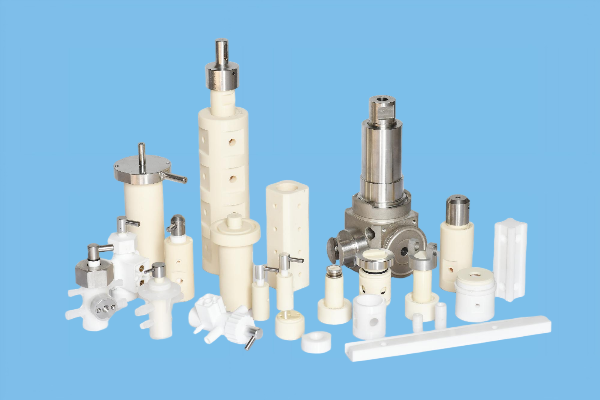

A hydraulic ceramic piston pump is a device that uses a ceramic piston to reciprocate in a hydraulic cylinder to transport or pressurize a liquid, suitable for handling corrosive media or where high wear resistance is required.

Core features

Ceramic plunger: Made of materials such as zirconia and silicon nitride, it the characteristics of high hardness, wear resistance, and corrosion resistance, suitable for conveying liquids containing solid particles or chemical media.

Hydraulic drive: plunger is driven by a hydraulic system (such as a hydraulic cylinder), providing stable and adjustable high-pressure output.

Structure: Common designs include single-, double-cylinder, and multi-cylinder configurations, with options for electric or diesel engine drive, and some models support variable frequency or explosion-proof configurations.

Typical

Industrial field: Matching with filter presses in sewage treatment, slurry transportation, chemical processes, and ceramic production.

Agricultural irrigation: Used in automatic sprinkler systems for farms and orchards, suitable for long-term operation due to its durability.

Other fields: Construction machinery, hydraulic testing, high-pressure cleaning, etc.

Precautions

Although the ceramic plunger is wear-resistant, it is a brittle material and should avoid severe impact idling.

When purchasing, it is necessary to choose the appropriate material and configuration based on the medium characteristics (such as corrosiveness, particle concentration) and working pressure.

Regular maintenance of the hydraulic system and inspection of plunger wear are key to ensuring longevity.

If you need more specific model recommendations or technical parameters, you can tell your use scenario and budget.