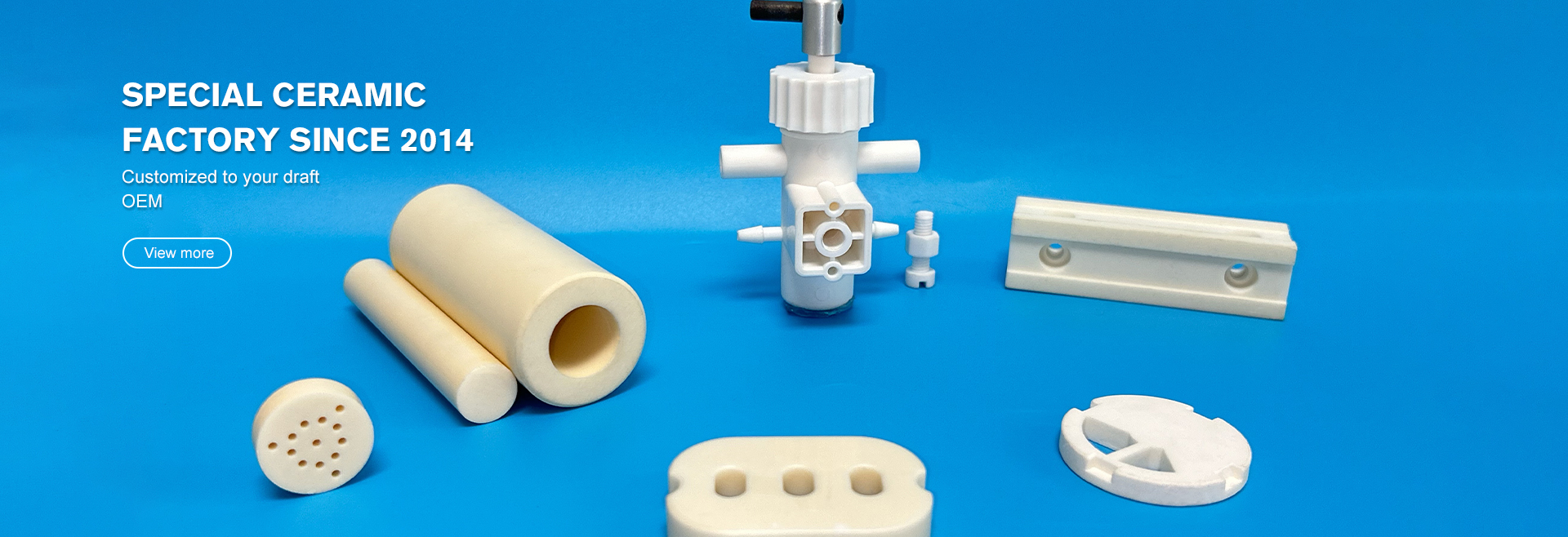

Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Ceramic plunger pump

HOMECeramic plunger pump

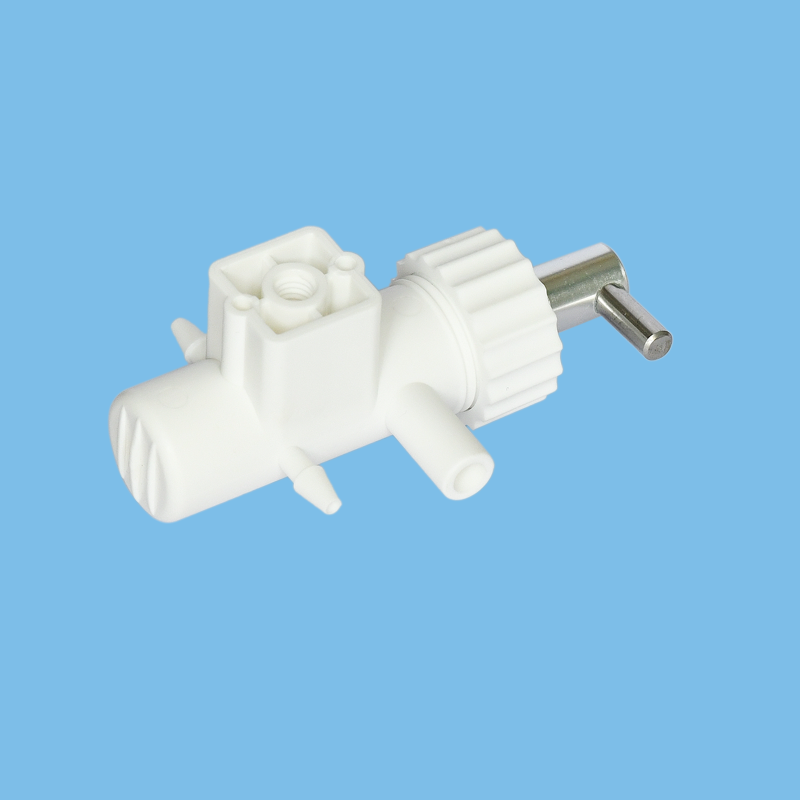

Ceramic pump core of filling machine

Ceramic pump core of filling machine

The ceramic pump core is the core component of the filling machine, made of ceramic materials such as zirconia and alumina, with the characteristics of corrosion, wear resistance and high precision, widely used in lithium battery electrolyte filling, pharmaceutical filling, chemical metering and other fields.

Its working principle is to change the volume of the sealed cavity through the precise fit between the ceramic plunger and the sleeve duringprocating motion, realizing the suction and discharge of the liquid. With the feedback of the sensor, it can achieve precise metering at a micro level.

How long is service life of a ceramic pump core?

The service life of a ceramic pump core usually ranges from 6 to 8 years, depending on the material and usage environment.

zirconia ceramic pump core, with its high toughness, high temperature resistance, and precise machining process (such as inner and outer circle grinding, drilling, polishing tolerance ±0.01), can achieve a service life of more than 8 years under ideal working conditions. And the nitride aluminum ceramic pump core, with its excellent resistance and high temperature resistance (melting point 2850°C), can maintain long-term stable operation in harsh environments such as chemical industry.

It should noted that the actual life will be significantly affected by the conveying medium (such as corrosion, particle content), working temperature, and daily maintenance.

Is the maintenance cost of ceramic pump core high?

The maintenance cost of a ceramic pump core is actually very low, and it can even save you a lot of money.

Its core advantage is ultrawear resistance and ultra-corrosion resistance, which means that the pump core has very little loss and the replacement frequency is greatly reduced. For example, in the chemical industry, metal pumps may need to replace the seal every few months, while the ceramic pump core can be used continuously for 18 months or even longer, saving nearly ten thousand yuan maintenance and consumable costs. In severe wear environments such as mines, its life is even 2-3 times that of ordinary metal pumps, and the failure rate can be reduced 70%.

Although the purchase price of the ceramic pump core itself may be slightly higher, in the long run, it saves maintenance costs, reduces downtime losses, and leakage risks, making its total cost very cost-effective. Therefore, the maintenance cost is not high, but can become a weapon for you to reduce costs and increase efficiency。

Its working principle is to change the volume of the sealed cavity through the precise fit between the ceramic plunger and the sleeve duringprocating motion, realizing the suction and discharge of the liquid. With the feedback of the sensor, it can achieve precise metering at a micro level.

How long is service life of a ceramic pump core?

The service life of a ceramic pump core usually ranges from 6 to 8 years, depending on the material and usage environment.

zirconia ceramic pump core, with its high toughness, high temperature resistance, and precise machining process (such as inner and outer circle grinding, drilling, polishing tolerance ±0.01), can achieve a service life of more than 8 years under ideal working conditions. And the nitride aluminum ceramic pump core, with its excellent resistance and high temperature resistance (melting point 2850°C), can maintain long-term stable operation in harsh environments such as chemical industry.

It should noted that the actual life will be significantly affected by the conveying medium (such as corrosion, particle content), working temperature, and daily maintenance.

Is the maintenance cost of ceramic pump core high?

The maintenance cost of a ceramic pump core is actually very low, and it can even save you a lot of money.

Its core advantage is ultrawear resistance and ultra-corrosion resistance, which means that the pump core has very little loss and the replacement frequency is greatly reduced. For example, in the chemical industry, metal pumps may need to replace the seal every few months, while the ceramic pump core can be used continuously for 18 months or even longer, saving nearly ten thousand yuan maintenance and consumable costs. In severe wear environments such as mines, its life is even 2-3 times that of ordinary metal pumps, and the failure rate can be reduced 70%.

Although the purchase price of the ceramic pump core itself may be slightly higher, in the long run, it saves maintenance costs, reduces downtime losses, and leakage risks, making its total cost very cost-effective. Therefore, the maintenance cost is not high, but can become a weapon for you to reduce costs and increase efficiency.