Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

Ceramic plunger pump

HOMECeramic plunger pump

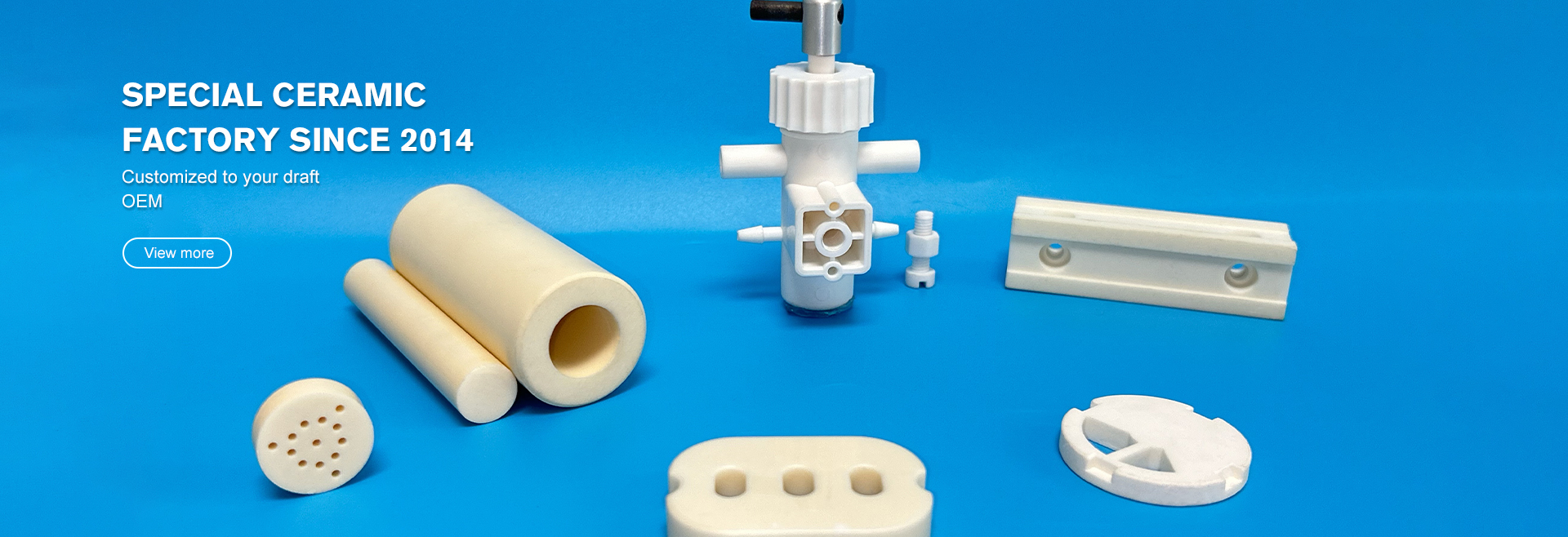

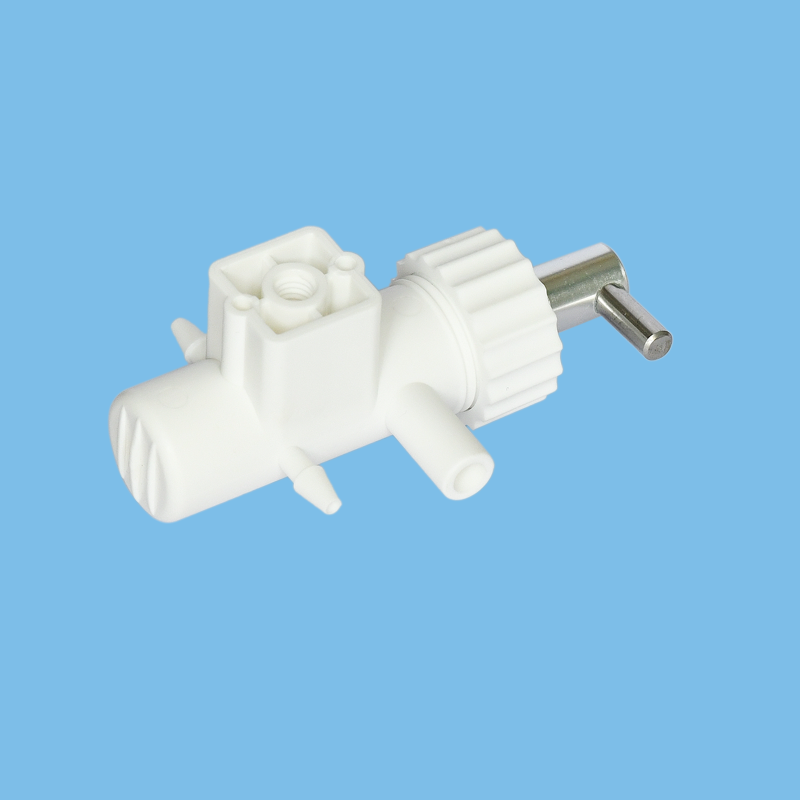

Liquid electrolyte ceramic filling pump core

Liquid electrolyte ceramic core;

The electrolyte ceramic pump core is a core component designed specifically for transporting strong acid and base electrolytes. Made of materials such as zirconia, it excellent corrosion resistance, high precision, and long-term stability, widely used in new energy fields such as lithium batteries and hydrogen energy.

Core Advantages

Corrosion Resistance: Zirconia ceramic has excellent chemical stability, capable of resistingte corrosion and preventing metal ion contamination, ensuring the purity of materials.

High-Precision Metering: With high hardness and smooth surface, the ceramic parts, with precision machining, can maintain a stable flow accuracy within ±0.5%, meeting micron-level requirements.

Abrasion and High-Temperature: Ceramic materials have the second-highest hardness after diamond, far exceeding metal in abrasion resistance, and can withstand high-temperature environments, extending service life.

How long is the service life of a ceramic pump core?

The service life of an electrolyte ceramic pump core typically ranges from 6 to 8 years mainly due to the excellent corrosion resistance, wear resistance, and high-temperature resistance of its zirconia ceramic material. However, the actual lifespan will be affected by the specific conditions you use, such as the corrosiveness of the electrolyte, temperature fluctuations, and the content of particulate matter in the medium.

What are the steps for an electrolyte ceramic pump core?

Power Off and Prepare: First, turn off the pump power to ensure safety. Get ready with the new pump core and necessary, such as a screwdriver.

Disassemble and Clean: Unscrew the pump cover bolts and remove the pump cover. Carefully clean away any residualte and impurities inside the pump to avoid affecting the new pump core's operation.

Replace the Pump Core: Take out the old pump core, being careful not damage the seal ring. Insert the new pump core into the pump cover, ensuring its axis is perfectly aligned with the pump cover opening, and the seal ring is in place.

Test Run: Tighten the pump cover bolts, connect the power, and test the pump's operation. Observe for any abnormal sounds or vibrations, ensuring everything normal.

The entire process must be carried out with care, and if you encounter any problems, it is advisable to contact a professional for assistance.