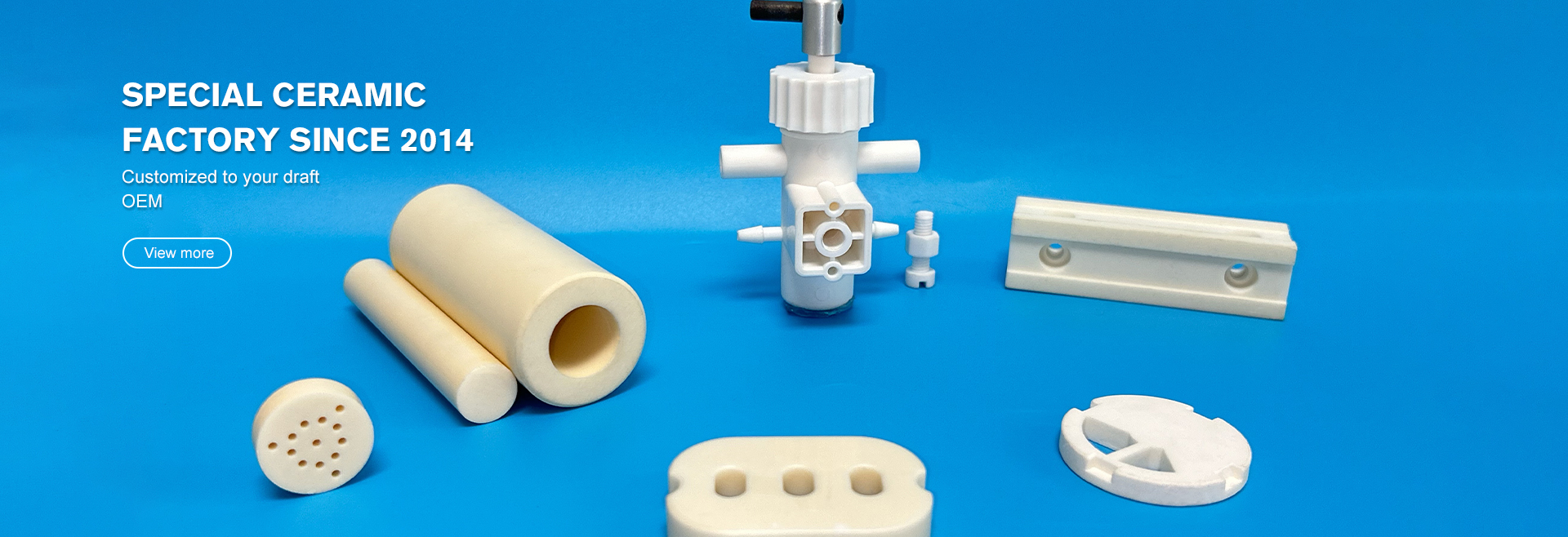

Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

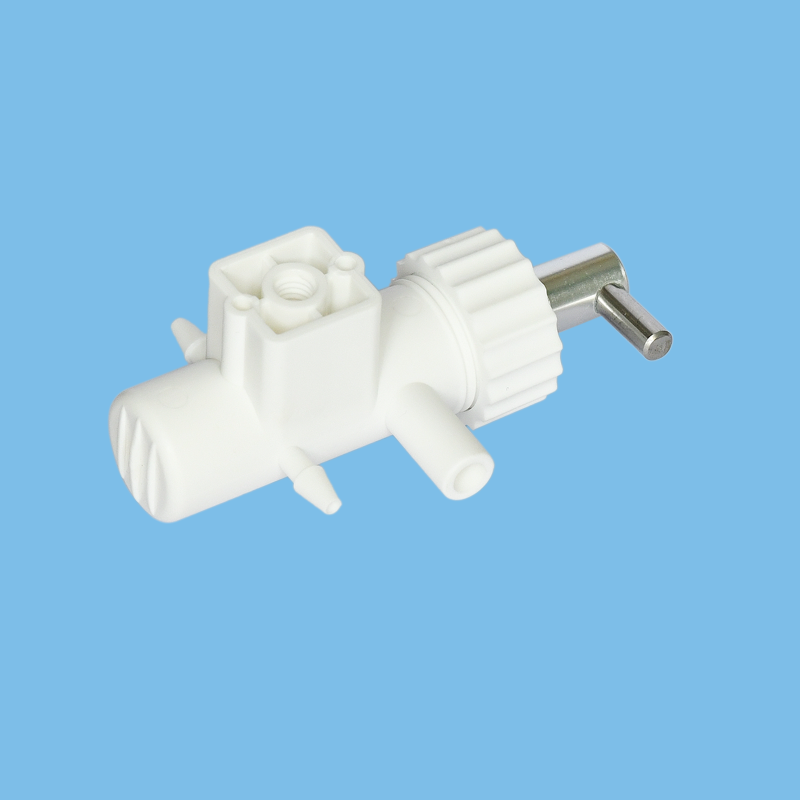

Ceramic plunger pump

HOMECeramic plunger pump

Ceramic plunger pump

The ceramic plunger pump is a high-pressure pump that uses the reciprocating motion of the ceramic plunger to achieve liquid delivery. It has the of corrosion resistance, wear resistance, and long service life. It is widely used in chemical, pharmaceutical, food, and other industries. Its working principle is to drive the plunger reciprocate in the pump cavity through the motor, forming a negative pressure to suck in liquid, and then discharging the liquid under high pressure. The working pressure can reach above100MPa.

Application scenarios

Chemical industry: Transportation of corrosive liquids (acids, alkalis, etc.)

Pharmaceutical industry: Transportation of high-purity liquids.

Food industry: Transportation of liquids with high sanitary requirements.

Maintenance points

ularly check the wear of seals and plungers.

Ensure the pump is firmly installed to avoid vibration affecting performance.

To determine whether the ceramic plunger pump needs, it is necessary to consider the following key indicators:

1. Abnormal performance signals

Decreased efficiency: Flow or pressure significantly lower than rated values, which be caused by plunger wear or seal failure.

Abnormal noise/vibration: Indicating wear or looseness of internal components (such as valve groups bearings).

Excessive temperature rise: Continuous temperature rise at friction points, which may be caused by poor lubrication or abnormal assembly clearance.

2. status inspection

Plunger and seal:

Check whether there are scratches, corrosion, or deformation on the plunger surface.

Seal integrity test: Plug the oil hole and pull out the plunger, if there is no suction or slow retraction, it needs to be replaced.

Wear characteristics:

The plunger shows milk-white grooves, comb-like fine lines at the beam, or wear at the sleeve oil inlet hole.

The seal ring should be tightened without leakage, too tight will accelerate wear.

3. Regular maintenance cycle

500 hours: Replace hydraulic oil, clean the filter, and check seals.

100 hours: Check connecting rod bolts, assembly clearance, and packing wear.

5000 hours: Regular overhaul, and a major overhaul is required at 0000 hours.

4. Medium and environmental impact

Corrosive medium: It is necessary to confirm the ceramic corrosion resistance grade to avoid surface corrosion pits

Particle content: High hardness particles can scratch the plunger and require additional filters.

Temperature fluctuation: Avoid sudden cooling and heating to prevent ceramic cracking

If any of the above anomalies occur, stop the machine for timely maintenance or replacement of parts.