Products

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

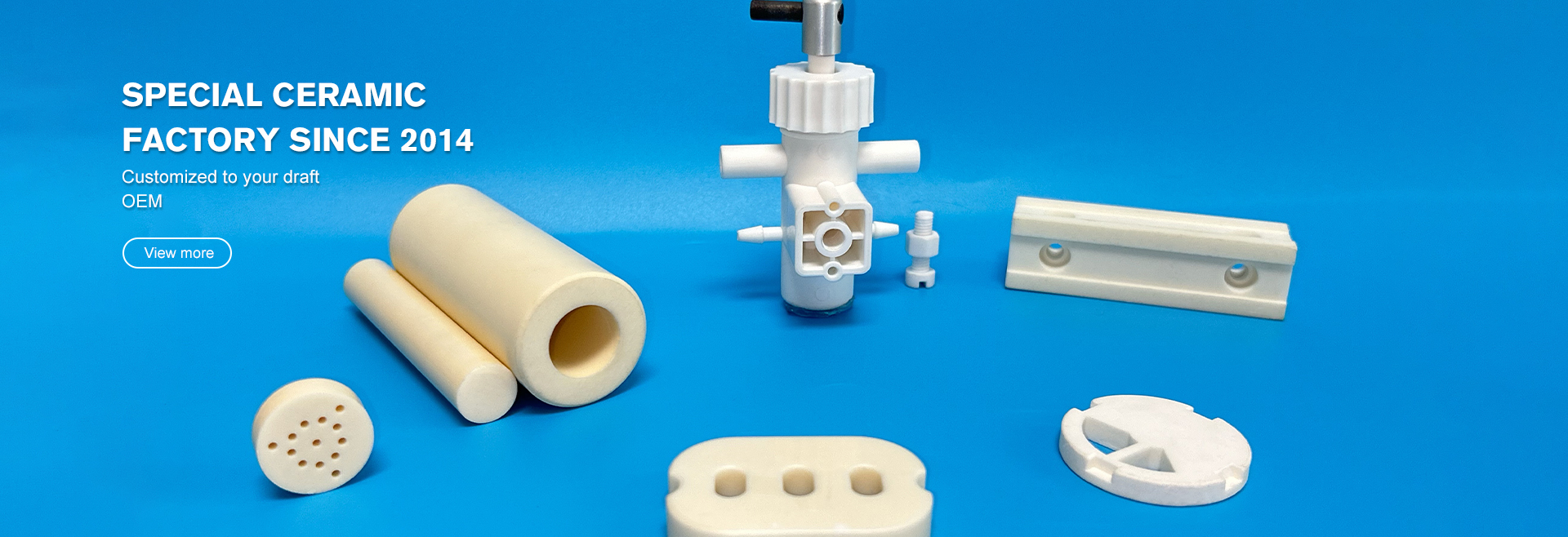

Ceramic plunger pump

HOMECeramic plunger pump

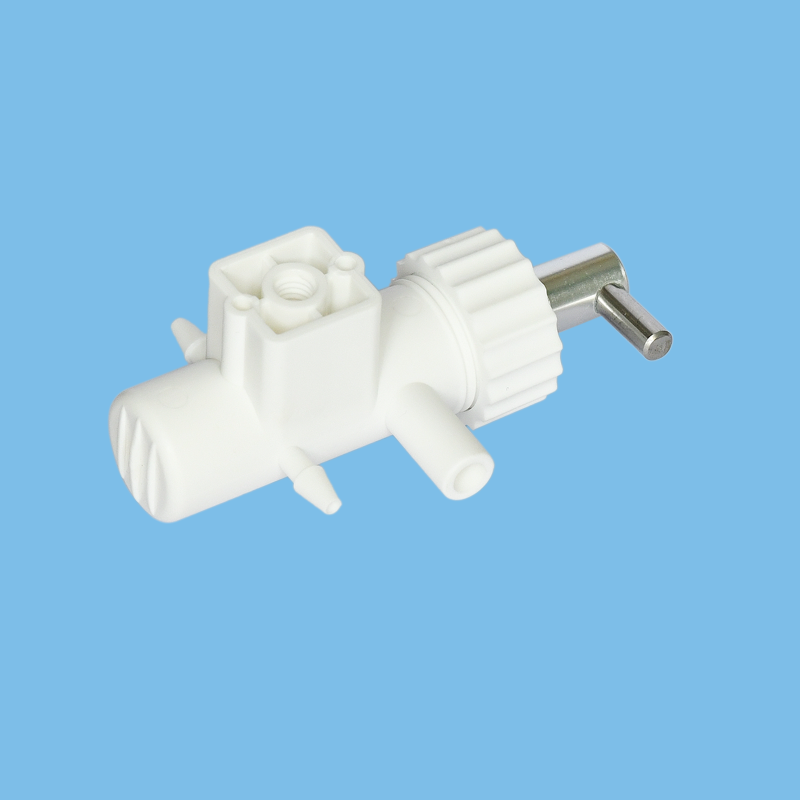

CNC pump ceramic pump core

CNC Pump Ceramic Core

CNC pump ceramic cores have a wide price range due to different materials and functions, mainly divided the following categories:

Zirconia Ceramic Pump Core: High precision, wear-resistant, and corrosion-resistant, with a price range of 10-200 yuan

Zirconia Ceramic Pump Core: High precision, wear-resistant, heat-resistant, and corrosion-resistant, with a range of 80-100-0 yuan

High-precision micro-graded ceramic metering pump: CNC step control, resistant to strong acids andis, with a price of 5000 yuan.

Ceramic pump cores have the characteristics of corrosion resistance, wear resistance, and high temperature resistance, making suitable for industries such as chemical engineering, semiconductors, etc.

When choosing a ceramic pump core, focus on the material, function, and your specific working conditions. Zconia ceramics are resistant to corrosion and wear, making them the preferred choice for harsh environments such as chemical engineering and semiconductors; alumina ceramics have a cost performance ratio and are suitable for general industrial scenarios. In terms of function, different needs such as lubrication, cooling, or metering require different selections. Prices range from to thousands of yuan, to be matched according to needs.

Material selection: Corrosion and wear resistance are key

Zirconia ceramics are theking of resistance," with a Mohs hardness of 8.5, resistant to strong acids and alkalis, and especially suitable for corrosive and high-wear environments such chemical engineering, electroplating, and new energy. Alumina ceramics have slightly lower hardness but are more cost-effective, making them suitable for general industrial applications.Selection tips

Define medium: Use zirconia for strong acids and alkalis, and alumina for general cooling.

Determine function: Choose correspondingly designed pump core based on whether it is for lubrication, cooling, or metering.

Budget match: Select a model with the right cost performance ratio on the importance of the equipment and the budget.