News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

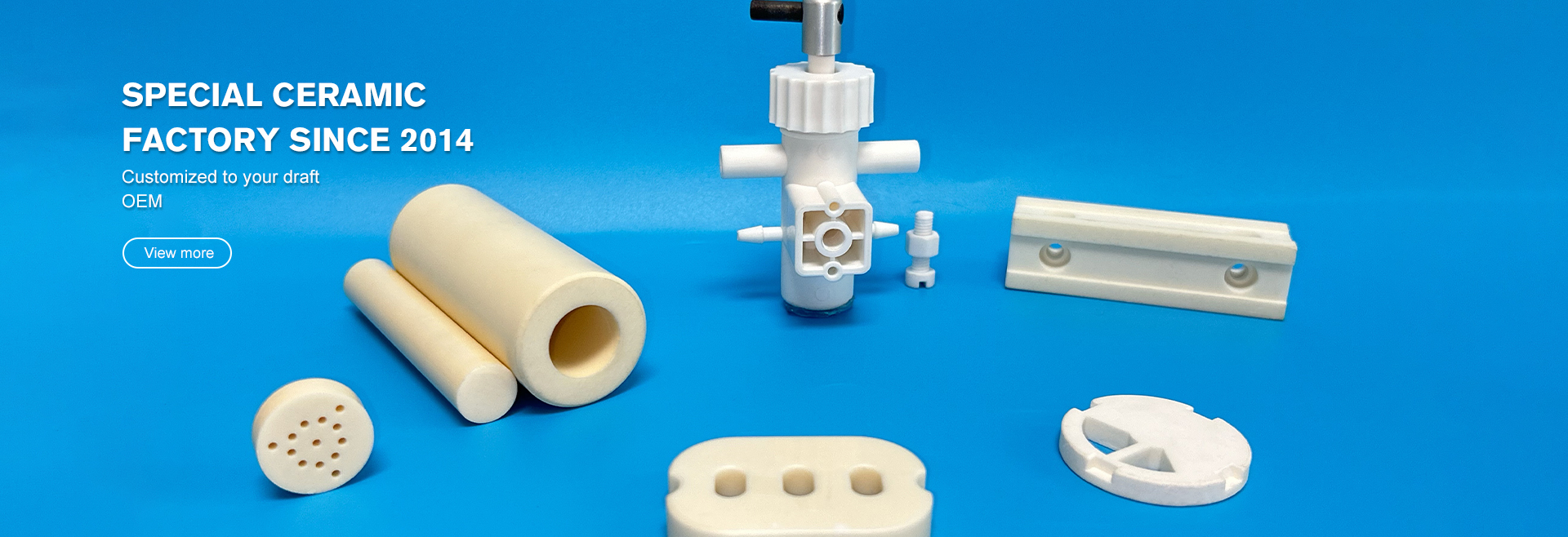

Ceramic plunger mud pump

2025-12-22 08:25:44 View:137The ceramic plunger slurry pump is a high-pressure conveying equipment that uses hydraulic drive and alumina ceramic pl, achieving stable slurry transportation through a double-cylinder double-action design. It is widely used in the ceramic, mining, metallurgy, and environmental protection fields.

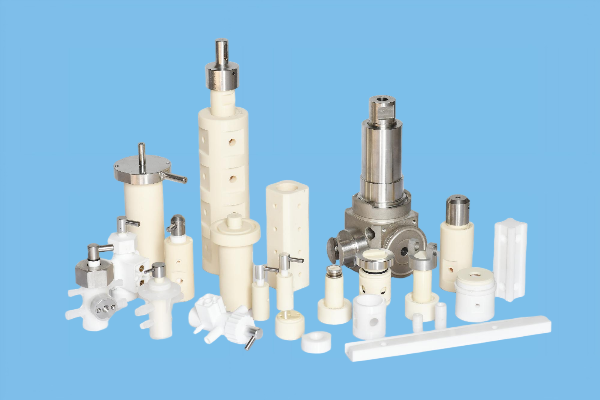

Principle and Technical Parameters

The core working principle of the ceramic plunger slurry pump is based on the principle of volume change: the hydraulic system drives the ceramic plunger reciprocate in the cylinder, and the suction and discharge processes are controlled by a check valve. When the plunger is pulled out, it forms a negative pressure to suck the slurry, and when it is pushed in, it compresses and discharges, achieving continuous transportation. Its technical parameters include:

Flow range: 0.160 m³h, suitable for different transportation needs;

Pressure range: 1.0–6.0 MPa, up to 20 MPacustomized models);

Medium adaptability: It can transport slurry with solid particles and density ≤ 2.5 kgm³, such as mud, tail or sludge;

Key components: alumina ceramic plunger (hardness HRA88-91), composite sealing system (rubber V-ring urethane compression ring), with abrasion resistance 6–8 times that of metal plunger.

Application Fields and Advantages

The pump performs exceptionally in pressure and high wear scenarios:

Application fields:

Ceramic industry: transport glaze, green body slurry, working pressure 1.8–2. MPa;

Mining metallurgy: handle tailings slurry, pressure 4.0–6.0 MPa, transportation distance over 500 meters;

Environmental protection field: feed for filter press, suitable for high concentration sludge (density 2.3–2.5 kgm³).

Core advantages

Long wear resistance and long service life: the ceramic plunger is corrosion-resistant and heat-resistant, with a service life of more than 15 years, and maintenance cost is only 1/10 of the centrifugal pump;

Energy saving and efficient: the constant pressure variable system automatically adjusts the flow, reducing the power by 40%–50%;

Easy operation: pressure is quickly adjusted through the overflow valve, and it supports self-suction (suction lift –8 meters).

Selection points:

Medium characteristics: avoid large particle materials, and choose the anti-corrosion model for corrosive media;

Flow margin: a 20% margin should be reserved for the rated flow, matching the actual working conditions.