News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

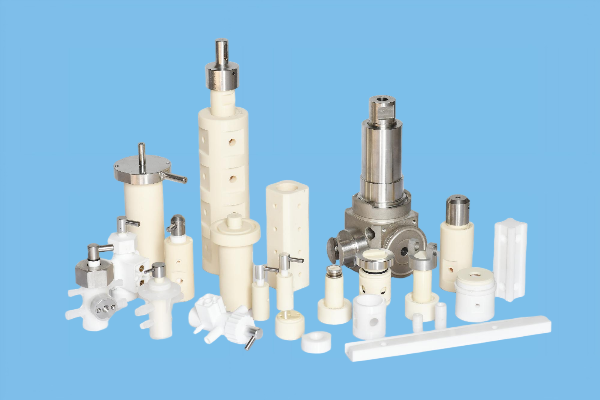

Hydraulic ceramic piston pump

2025-12-24 09:14:37 View:148The working principle of the hydraulic ceramic plunger pump is actually quite intuitive. The core is to change the volume of the sealed cavity the reciprocating motion of the plunger to achieve oil suction and pressure. Let me break down its working process for you:

1. Core Working Principle

Oil suction process: The plunger moves outward under the action of the driving mechanism (such as a swash plate or crankshaft), the volume of sealed cavity gradually increases, forming a local vacuum, and hydraulic oil is sucked in under the action of atmospheric pressure.

Oil pressure process: The plunger retract into the cylinder, the volume of the sealed cavity decreases, the oil is squeezed and the pressure increases, and when the pressure exceeds the system pressure, the high-pressure oil is out.

2. Continuous Working Mechanism

Multi-plunger design: Typically, multiple plungers (such as 7, 9, or 1) are configured, evenly distributed around the circle, and driven by a swash plate or cam, to achieve continuous oil suction and pressure.

Flow regulation: adjusting the angle of the swash plate, the stroke of the plunger can be changed, thereby controlling the flow rate.

3. Advantages of Ceramic PlungersWear and corrosion resistance: Ceramic plungers (such as zirconia) have high hardness and strong compressive strength, suitable for conveying corrosive (such as acid and alkali) or slurry containing particles.

Long life: Ceramic materials have excellent wear resistance and low maintenance costs, suitable for high pressure large flow, and continuous working environments.

4. Typical Applications

Industrial field: Petrochemical industry, automobile manufacturing, machinery manufacturing, industrial automation, etc

Environmental protection field: Industrial sewage treatment, slurry transportation, etc.

If you have specific use scenarios or parameter requirements, I can help you analyze in.