News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Hydraulic ceramic plunger slurry pump

2025-12-27 11:15:23 View:122Hydraulic Ceramic Plunger Slurry Pump

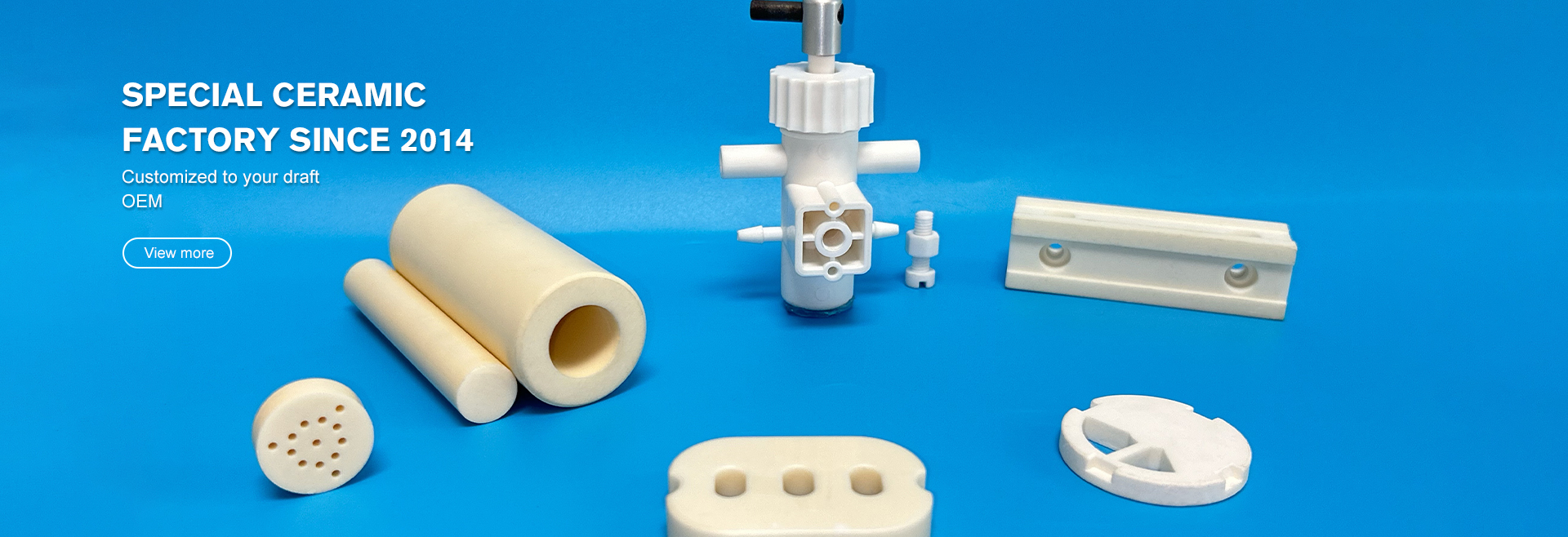

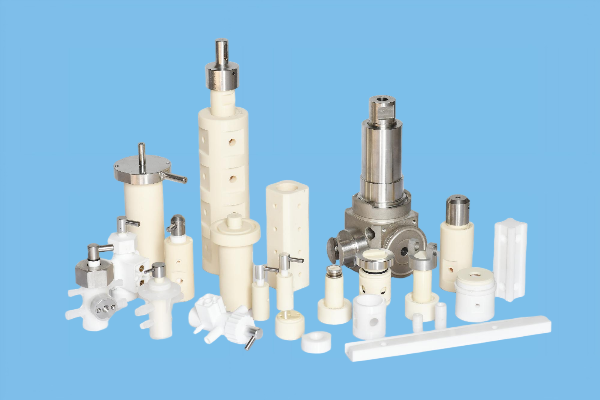

The ceramic slurry hydraulic plunger pump an industrial equipment that uses hydraulic drive and alumina ceramic plungers. It achieves stable and high-pressure slurry transportation through a double-cylinder double-action design and is used in the ceramic, mining, metallurgy, and environmental protection fields.

Working Principle and Technical Features

The core operation of the ceramic slurry hydraulic plunger is based on the principle of volumetric change: the hydraulic system drives the plunger to reciprocate in the cylinder, and the suction and pressure of the slurry realized by changing the volume of the sealed cavity. The specific process includes:

Suction Stage: When the plunger moves outward, the volume of the cavity increases form a negative pressure, the one-way suction valve opens, and the slurry enters the pump body.

Pressing Stage: When the pl moves inward, the volume of the cavity decreases, the pressure of the slurry increases, the discharge valve opens, and the high-pressure slurry is transported to the target position

Technical advantages include:

Abrasion Resistance: The plunger adopts alumina ceramic material (hardness HRA88-91, which improves the service life by 6-8 times compared with metal plungers.

Pressure Stability: The hydraulic reversing and oil device and the bladder-type accumulator design make the pressure fluctuation ≤0.3MPa, and support constant pressure automatic variable output.

Energy E: Under the same flow, the motor power is 1-2 models lower than that of the centrifugal pump or screw pump, and the energy consumption is significantly reduced

Key Parameters and Model Series

The technical parameters and model selection of the pump need to be customized according to the working conditions, and the main indicators include:

Performance Range:

Flow: 0.1–60 m³/h, covering the transportation needs from fine glaze to tailings slurry.

Pressure: 1.0–6.0 MPa, commonly used 1.8–2.0 MPa in the ceramic industry, and can reach4.0–6.0 MPa in the mining field.

Medium Adaptability: Can transport slurry with density ≤2.5 kgm³ containing solid particles.

Application Fields and Maintenance Points

Core Application Scenarios:

Ceramic Industry: Transport gl and green body slurry, working pressure 1.8–2.0 MPa, with ball mill and spray dryer tower.

Mining and Environmental: The pressure reaches 4.0–6.0 MPa when dealing with tailings slurry, with a conveying distance of more than 500 meters in the field of sludge dewatering, it can reduce the water content and achieve the goal of volume reduction.

Maintenance Specifications:

Hydraulic oil management: Use 46# anti-wear hydraulic oil, oil temperature ≤60℃, replace every 6–8 months.

Fault handling: When the pressure fluctuation exceeds 0.3 MPa, overhaul the reversing valve seal ring; if the leakage amount is >5%, adjust pressure ring or replace the V-type seal.

Shutdown maintenance: Flush the pipeline to prevent freezing cracks, and the parallelism deviation of the end of the sealing component shall be ≤0.5 mm.