News

LATEST NEWS

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Ceramic slurry plunger pump

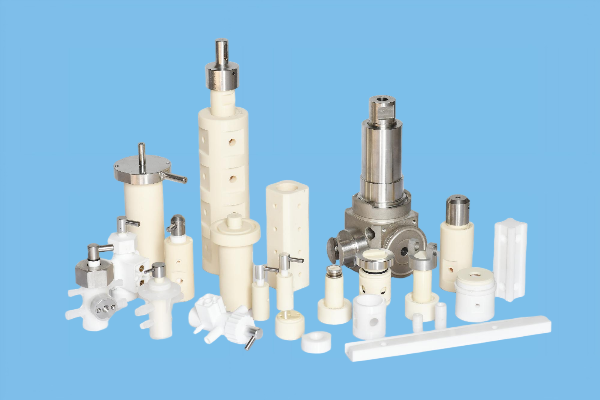

2025-12-26 08:13:59 View:136The working principle of the ceramic slurry plunger pump is actually quite intuitive. The core is to drive the ceramic pl to do reciprocating motion through hydraulic pressure, forming a pressure difference to suck and discharge slurry. Let me break down the specific process for you:

1. Core and working process

Structure composition:

It mainly consists of pump body, pump cylinder, ceramic plunger, inlet and outlet valves, etc. The ceramic plunger is core, responsible for reciprocating motion in the pump cylinder, to achieve the suction and discharge of the fluid.

Working principle:

Slurryction stage: The plunger moves backward, a negative pressure is formed in the pump cylinder, the inlet valve opens, and the slurry is sucked into the pump cylinder.Slurry discharge stage: The plunger moves forward, the pressure in the pump cylinder increases, the outlet valve opens, and the slurry is discharged from the pump.

Through the continuous reciprocating motion of the plunger, the slurry can be continuously transported.

2. Key technologies and advantages

Oil supplement device

Through the double oil supplement and reversing design, automatically supplement oil to the low-pressure area when the plunger is reciprocating, prevent the phenomenon of cavitation caused insufficient oil, ensure the synchronous drive of the hydraulic cylinder, and make the pump stable under 6.0MPa high pressure.

Sealing system:The sealed space formed by the cylinder body and the plunger hole adopts carbon fiber soft filler seal, and is matched with a low-resistance conical check valve, which can pass through high-viscosity electrolyte.

Power transmission:

The crankshaft makes the connecting rod do circular motion, and the crosshead converts it the up-and-down piston motion of the plunger. When the plunger goes down, it sucks liquid, and when it is pushed up, it discharges liquid When the oblique groove is aligned with the oil return hole, the oil supply stops. By adjusting the angle of the oblique disc, the flow can also be controlled like stepping the gas pedal.

3. Application scenarios

Ceramic plunger pumps, with their wear-resistant, corrosion-resistant, and high-pressure transportation characteristics, are used in sewage treatment, ceramic industry, coal industry and other fields. For example, in the sludge dewatering of plate and frame filter press, it can stably the pressure transportation of slurry; in the ceramic industry, it can also ensure the stability of slurry transportation and avoid pollution.

I hope this explanation can help you quickly its working principle!

Want to understand the maintenance skills of the ceramic plunger pump in depth? I can help you sort out a checklist for checking key components to extend life of the equipment~