News

LATEST NEWS

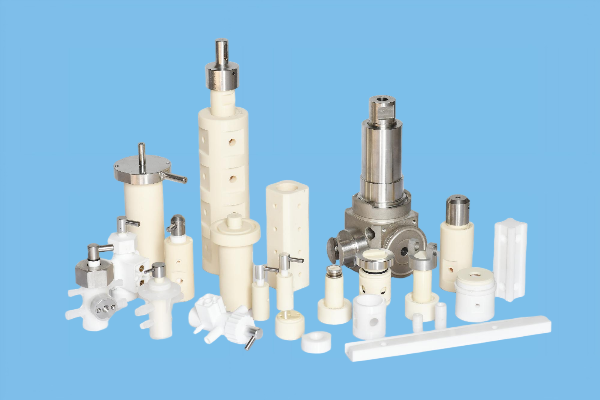

- 01Application of ceramic plunger pump

- 02The structure and principle of ceramic pumps

- 03Alumina ceramic properties

- 04Ceramic and stainless steel differences of three-cylinder plunger pump

- 05Common faults of ceramic plunger pump

- 06Energy-saving ceramic piston pump

- 07Ceramic Plunger Pump Parts

- 08Ceramic slurry plunger pump

- 09Hydraulic ceramic piston pump

- 010Working principle of ceramic plunger pump

Address:1st Floor, Zixiang Road, Pingshan District, Shenzhen, Guangdong Province

Zip Code: 518100

Phone: +86 13410681808

E-mail:glzmdy@163.com

News

HOMENews

Application of acid-resistant ceramic pump

2025-12-25 08:28:10 View:137Acid-resistant ceramic pumps, with their superior corrosion resistance, wear resistance, and high-temperature resistance, play a crucial in various industrial sectors, particularly for transporting strong acids, strong bases, high-viscosity, or particle-containing corrosive media.

In the chemical and petro industries, acid-resistant ceramic pumps are ideal for handling corrosive chemicals, such as reliably transporting concentrated sulfuric acid in the production of sulfuric acid, avoiding the rapid corrosion of metal pumps; while in the synthesis devices of benzene and naphthalene compounds, liquid ring vacuum pumps made of high-strength industrial ceramic materials can withstand complex chemical environments and sealing reliability.

In the field of environmental protection and sewage treatment, this type of pump is used to transport raw water with high turbidity, acidic and alkal wastewater, or corrosive sludge. Its alumina ceramic material has a Mohs hardness of 9, which can resist particle scouring and is not prone to impurity precipitation, ensuring the long-term stable operation of processes such as reverse osmosis pre-treatment, and reducing maintenance costs.

In the manufacture of electronics and semiconors, the precise flow control and chemical stability of acid-resistant ceramic pumps are essential, such as ensuring the accuracy of electrolyte injection in the lithium battery filling process, or accurately photoresist and other reagents in chip manufacturing, avoiding contamination affecting product yield.

In the mining and metallurgical processes, pumps need to cope with high-wear pulp or high-temperature media, and silicon carbide ceramic pumps with a hardness of HRA92 or above, and wear resistance 10-20 times that of metals, are suitable for transporting copper ore pulp or acid pickling waste liquid treatment, while withstanding temperatures of 200-500℃, reducing equipment failure rates

In the fields of biopharmaceuticals and others, acid-resistant ceramic pumps support aseptic preparation of micro-filling, in compliance with hygien standards; in electroplating, printed circuit board cleaning, and other scenarios, they are used to circulate acidic drugs, and their self-priming design and corrosion resistance safe and efficient operation.